6.5. THE FIRST OIL FILLING

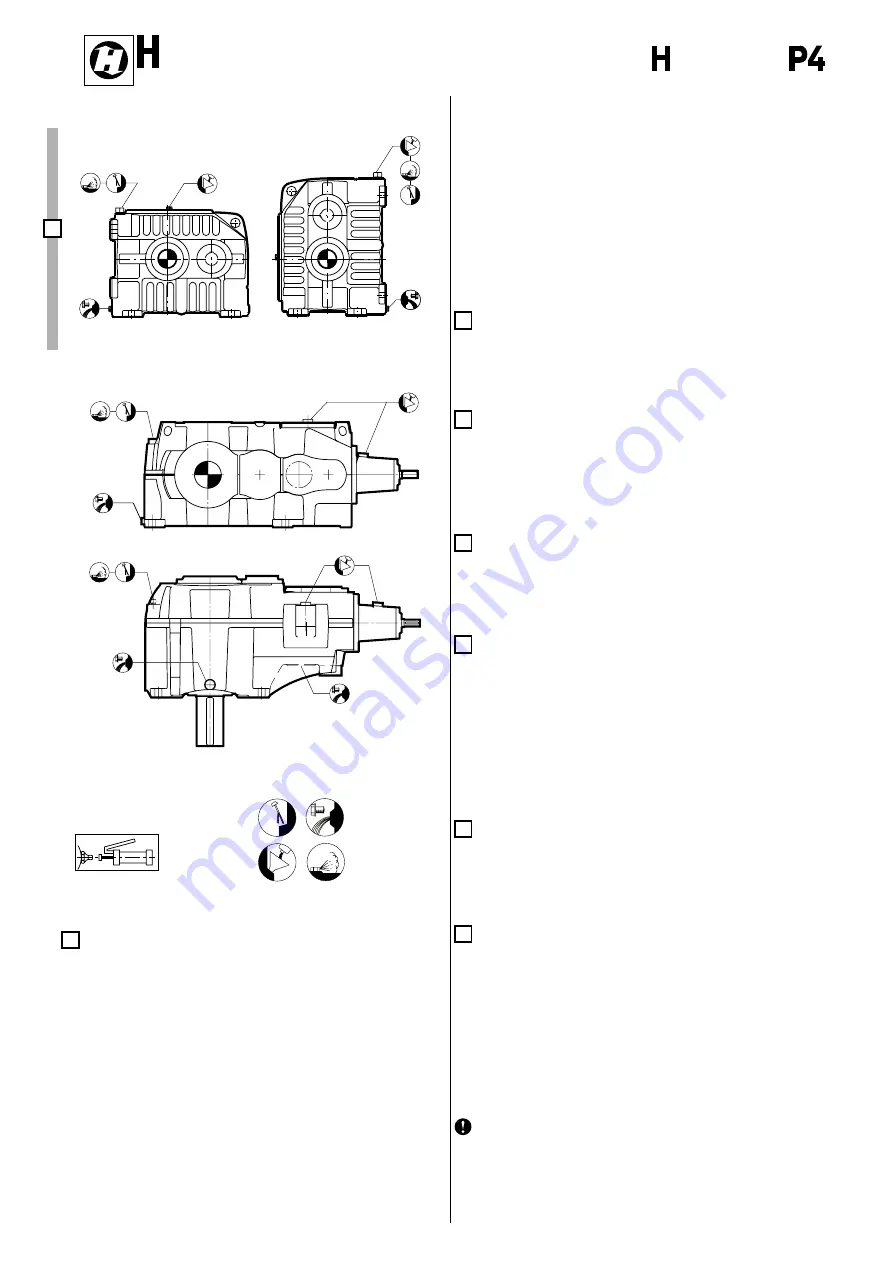

(see fig. 5)

Fill units only after final installation, especially gear units with vertical

downwards shafts, to prevent oil splashing over drywell during handling.

Fill the gear unit exclusively through the oil filling open-

ing which is provided in the inspection cover for that

purpose. In that way, all bearings are lubricated with

fresh oil.

Note :

- Additional oil filling of the bearing housing.

4-stage horizontal gear units with right angle shafts

(QHR.4) and 3- and 4-stage vertical gear units with

right angle shafts (QVR.3 + QVR.4) require on initial

oil filling also an additional oil filling of the bearing

housing.

See special sticker on gear unit.

The additional oil quantity is mentioned on the

certified drawing and on the sticker.

M

M

M

M

M

M

- Oil filling of a gear unit with M1 or M3 motor base.

Units with horizontal shafts (QH ..) equipped with a motorbase M1 and

M3 must be filled on initial filling with a small quantity of oil through the

inspection cover located in the top face of the gear unit (see special sticker

on gear unit).

If easy access to the oil filler plug is prevented through lack of space

between the motor base and the gear unit upper face, the motor base

should be raised following removal of the belt.

For gear units with M1 motor base the normal oil filling plug is located at

the side of the output shaft, opposite the side where the dipstick is

located.

For gear units with M3 motor base the normal oil filling plug is located at

the side of the dipstick.

If the gear unit is filled with storage oil, it has to be drained and it may in

some instances be necessary to rinse the gear unit with the selected oil before

starting up. Check with the oil supplier.

6.6. GREASE SELECTION

(see table page 36)

Use only high quality greases, with EP-additives and consistency

NLGI-Grade 3.

Greases with EP-additives and consistency NLGI-Grade 2 may be used for re-

greasable labyrinth type seals and grease lubricated lower bearing of the

low speed shaft.

6.7. GREASE LUBRICATION POINTS

(see fig. 5)

All greasing points for bearings which are not oil lubricated and for labyrinth

seals are equipped with nipples according to DIN 71412 and have been

filled before shipment.

The total number of nipples is indicated on the nameplate.

Some built-on backstops are grease lubricated.

For detailed information refer to appropriate leaflet supplied with this

manual.

6.8. OIL DRAINING

(see fig. 5)

Drain the oil while unit is still warm.

To facilitate oil drai-

ning, remove dipstick. Drain units having a large oil volume through drain

plug. Use portable pump. With some executions a small quantity of oil

remains beneath the high speed bearings. This oil can be drained by means

of a second drain plug (1).

6.9. VENTILATION

(see fig. 5)

To prevent pressure build-up, the gear unit is provided with a breather which

is generally integrated in the dipstick.

Take care and check regularly that this breather

does not become clogged.

For some applications, the dipstick with breather hole is replaced by one

without breather hole in combination with an anti-dust or anti-humidity

breather.

7. COOLING

Heat generated in the gear unit due to friction and churning of the oil, must

be dissipated through the housing into the environment.

It is important not to decrease the heath dissipation capacity of the housing.

Regularly clean the surface of the housing.

7.1. SEPARATE AIR COOLING

7.1.1. Fans

One or two fans may be mounted on gear unit shafts.

Check regularly that the air inlet and the air

outlet are not obstructed.

Fans need no special maintenance, except occasional cleaning.

7.1.2. Air-oil coolers

The service manual of the lubrication and cooling system gives detailed

information about the air-oil cooler.

7.2. SEPARATE WATER COOLING

All water cooling systems must be connected to a non-calcareous water

supply. See also service manual on lubrication and cooling system and/or

technical leaflets on specific instrumentation. The use of seawater must be

specified with the order; coolers suited for use of seawater are available.

When unit is not operating and freezing temperatures may occur, water must

be drained from cooling system. Drain facilities have to be provided by end

user.

Unless otherwise stipulated, the water flow indicated on the dimensional

drawing is the required rate for water at 20 C (70 F).

According to load, ambient temperature and the water temperature a lower

rate will suffice. Adjust waterflow to obtain an oil working temperature bet-

ween 60 and 80 C (140 and 180 F).

9

ansen

dipstick

oil filling

oil draining

ventilation

grease lubrication

points

Type and position of the

stickers : refer to certified

drawing and gear unit

FIG. 5

T R A N S M I S S I O N S

ansen

®

- Single stage gear units

(1) see 6.8

QHP.1

QHP.1W

- Multi stage gear units

M

n