G900X/G950 Installation and Maintenance Manual – Non LRU Specific Installation Information

Page 13-5

190-00719-00

Revision D

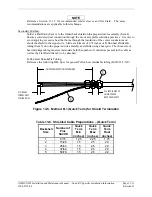

Table 13-5. Shielded Cable Preparations for Garmin Connectors

Backshell

Size

Number

of Pins

Std/HD

Float

Min

(inches)

Float

Max

(inches)

Ideal

Float

(inches)

Window

Min

(inches)

Window

Max

(inches)

Ideal

Window

(inches)

1 9/15

1.25

2.25

1.75

2.75

5.25

4.25

2 15/26

1.5 2.5 2.0 3.0 5.5 4.5

3 25/44

1.5 2.5 2.0 3.0 5.5 4.5

4 37/62

1.5 2.5 2.0 3.0 5.5 4.5

5 50/78

1.5 2.5 2.0 3.0 5.5 4.5

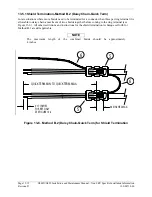

2.

At one end of a shielded cable (item 4) measure a distance between “Window Min” to “Window

Max” (Table 13-5) and cut a window (max size 0.35”) in the jacket to expose the shield (see

Figure 13-2). Use caution when cutting the jacket to avoid damaging the individual braids of the

shield. When dealing with a densely populated connector with many cables, it may prove

beneficial to stagger the windows throughout the “Window Min” to “Window Max” range. If

staggering is not needed the “Ideal Window” length is recommended.

Suggested tools to accomplish the window cut:

•

Coaxial Cable Stripper

•

Thermal Stripper

•

Sharp Razor Blade

3.

Connect a Flat Braid (item 6) to the shield exposed through the window of the prepared cable

assembly (item 4) from step 2. The Flat Braid should go out the front of the termination towards

the connector. It is not permitted to exit the rear of the termination and loop back towards the

connector (see Figure 13-2). Make this connection using an approved shield termination

technique.

NOTE

FAA AC 43.13-1B Chapter 11, Section 8 (Wiring Installation Inspection Requirements)

may be a helpful reference for termination techniques.

Preferred Method:

Slide a solder sleeve (item 5) onto the prepared cable assembly (item 4) and connect the

Flat Braid (item 6) to the shield using a heat gun approved for use with solder sleeves. It

may prove beneficial to use a solder sleeve with a pre-installed Flat Braid versus having

to cut a length of Flat Braid to be used. The chosen size of solder sleeve must

accommodate both the number of conductors present in the cable and the Flat Braid (item

6) to be attached.