PG9602™ OPERATION AND MAINTENANCE MANUAL

© 2011 Fluke Calibration

Page

44

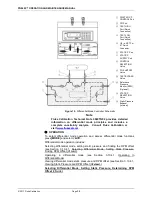

To install the AMH on the PG9000 platform, proceed as follows (see Figure 16).

Prepare the AMH:

Before loading the masses, perform the AMH

initialization procedure described in Section 2.4.10. This assures that the

AMH mass selection columns and pins are all correctly positioned.

Make sure that the mass lifting shaft is NOT installed on the mass bell.

Lower the AMH onto the PG9000 Platform:

Grasping the AMH by the

horizontal platform in its middle, lift the AMH above the PG9000 platform

and masses. Align it so that the cable and pneumatic connections line up

with the connections on the rear side of the PG Base. Center the AMH over

the mass load and gently lower it down until the AMH feet enter the holes in

the PG9000 Platform.

Assure that all three feet fully enter and seat in

the platform holes.

Tighten the platform set screws using a 2.5 mm allen

wrench provided in the AMH accessories, one for each of the feet.

Install the mass lifting shaft:

Slip the threaded end of the shaft down through

the hole in the center of the mass lifter. Thread the shaft into the binary mass

carrier by holding and rotating the trim mass tray. Note that shaft has a left

hand thread so it must be rotated counter-clockwise to tighten it. Use the 3 mm

allen wrench T-bar supplied in the AMH-100 accessories to tighten the

assembly until you feel the mass start to rotate.

Caution

Be sure that the mass lifting shaft is fully threaded into the

binary mass carrier. Thread it by hand, then tighten it using the

allen wrench supplied with the AMH until you feel the masses

rotate. If the mass lifting shaft is not fully threaded, the mass

will not align properly with the AMH mass handling columns

and pins and damage may result.

Connect the AMH drive, vent and electrical connections:

The drive and

vent connections are quick connect fittings. Drive is designated by a red

band. Vent is designated by a blue band. Mate the AMH power and signal

cable to the connector on the PG base.

If preparing to operate with vacuum under the bell jar, place the Bell

Jar onto the PG9000 platform:

Using the handles on the sides lift the Bell Jar

above the PG9000 platform and masses. Center it over the mass load and

gently lower it down until the bottom circumference of the Bell Jar reaches the

PG9000 vacuum plate. Check that the vacuum chamber is well aligned on the

vacuum plate. The Bell Jar may be rotated on the platform to the most

convenient position. Make the reference vacuum connection if the KF40

connection on the side of the AMH is being used.

If preparing to operate with vacuum under the bell jar, make sure the

vacuum vent line is connected to a vacuum pump and not open to

atmosphere. If operating without vacuum in the bell jar, open the AMH

Vent port atmosphere.

The PG9000 with AMH is now ready to operate (see Section 3).

Caution

Do not operate the AMH when using a PG9000 in “absolute by

vacuum” mode without

having a vacuum supply connected to

AMH-100’s Drive Vacuum port. Always check that the AMH is

supplied with vacuum before establishing reference vacuum in

the bell jar. Do not plug the AMH drive vacuum port. Doing so

may result in damage to the binary mass pins and/or binary

masses (see Section

Summary of Contents for PG9000 Series

Page 10: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page X Notes...

Page 128: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 118 Notes...

Page 164: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 154 Notes...

Page 188: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 178 Notes...

Page 192: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 182 Notes...