PG9602™ OPERATION AND MAINTENANCE MANUAL

© 2011 Fluke Calibration

Page

172

Caution

In reassembly, the two sleeve retaining screws (5) MUST be reinstalled before

pressure is applied to the piston-cylinder module. Damage to equipment and injury to

personnel may result from pressurizing the piston-cylinder module without the sleeve

retaining screws installed.

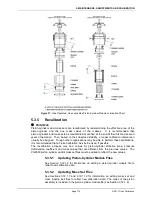

To reassemble follow the steps above in reverse order. Follow the notes carefully and

refer to the lubrication recommendations in Section 5.3.4.

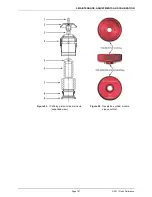

Figure 26.

50, 100 and 200 kPa/kg gas piston-cylinder modules (exploded view)

5.3.3

Cleaning Piston-Cylinders

There are two general methods for cleaning a piston-cylinder. They are a water / detergent

method, or a quicker method using Windex

®

brand (or equivalent) glass cleaner.

Caution

•

Never

•

Do not undertake piston-cylinder module disassembly without

familiarizing yourself with Section 5.3.1 of this manual. Incorrect

disassembly may damage or destroy the piston-cylinder element.

touch the lapped surfaces (polished appearance) of the piston or

cylinder with your bare hands. Body oils and acids can permanently etch

the surfaces.

Summary of Contents for PG9000 Series

Page 10: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page X Notes...

Page 128: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 118 Notes...

Page 164: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 154 Notes...

Page 188: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 178 Notes...

Page 192: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 182 Notes...