DIRECTION AND DRIVE SELECTOR

Page F-4

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

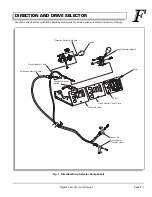

Raise the cowl and latch the support. Unscrew and

remove the knob (item 1) from the direction selector han-

dle (item 2) (Ref Fig. 5 on page F-4). Remove the lock

nut (item 3) and pivot shaft (item 4) attaching the drive

selector bracket (item 5) to the shifter housing (item 6)

from back side of dash. Remove the drive selector cable

(item 7) (Ref Direction And Drive Selector Cables Adjust-

ment Section on page F-2). Remove the drive selector

from the vehicle.

Installation of drive selector is the reverse of disassembly

using new lock nut.

Drive selector handle should be in 2 wheel drive position

during assembly of new components.

Tighten the hardware per torque specification table

below.

Proximity Sensor Switch Replacement

Tool List

Qty. Required

Digital Volt Ohm Meter (DVOM) .................................. 1

Drill bit ......................................................................... 1

Drill .............................................................................. 1

Proximity Sensor Switch Testing Method

To test the proximity sensor switch, carefully separate the

wire harness at the sensor. Move the drive control to the

4 wheel drive position (Ref Fig. 6 on page F-4). Select

the audible continuity setting on the DVOM. Insert the

two DVOM test probes into the harness from the sensor.

If the sensor is working properly, the DVOM display will

indicate 00.0 and the audible device will sound, indicat-

ing continuity. If the switch is not working properly, no

continuity will be indicated. If the 4 wheel drive indicator

light stays illuminated in both the 2 wheel & 4 wheel drive

positions, the sensor has failed in the closed position and

must be replaced.

Proximity Sensor Switch Replacement

To remove the proximity sensor switch requires that two

rivets be removed:

Remove the rivet head by drilling into the rivet head

using a sharp drill bit slightly larger than the shank of the

rivet. Apply light pressure to prevent damage to the rivet

mounting hole. Remove the rivet and remove the proxim-

ity sensor switch (Ref Fig. 7 on page F-4).

Install a new proximity sensor switch using new rivets.

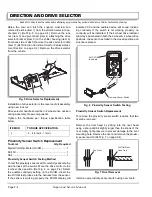

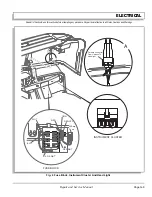

Fig. 5 Drive Selector Replacement

ITEM NO

TORQUE SPECIFICATION

3

6 - 8 ft. lbs (8 - 11 Nm)

4

3

5

6

7

2

1

Fig. 6 Proximity Sensor Switch Testing

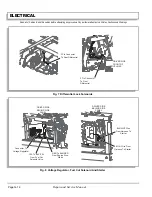

Fig. 7 Rivet Removal

Proximity Sensor Switch

BEEP

Set DVOM

to audible

Pop Rivet

Drill Out Rivet

Head Only

Summary of Contents for ST 4X4

Page 6: ...Page iv Repair and Service Manual TABLE OF CONTENTS Notes...

Page 10: ...Repair and Service Manual SAFETY INFORMATION Page viii Notes...

Page 12: ...GENERAL INFORMATION ROUTINE MAINTENANCE Page A ii Repair and Service Manual Notes...

Page 24: ...SAFETY Page B ii Repair and Service Manual Notes...

Page 34: ...BODY AND TRUCKBED Page C ii Repair and Service Manual Notes...

Page 50: ...BRAKES Page D ii Repair and Service Manual Notes...

Page 68: ...CONTINUOUSLY VARIABLE TRANSMISSION CVT Page E ii Repair and Service Manual Notes...

Page 74: ...DIRECTION AND DRIVE SELECTOR Page F ii Repair and Service Manual Notes...

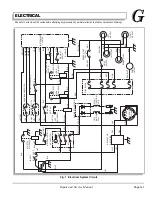

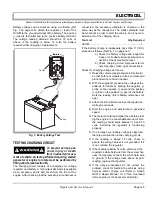

Page 80: ...ELECTRICAL Page G ii Repair and Service Manual Notes...

Page 114: ...FRONT SUSPENSION AND STEERING Page J ii Repair and Service Manual Notes...

Page 128: ...FUEL SYSTEM Page K ii Repair and Service Manual Notes...

Page 136: ...PAINT Page L ii Repair and Service Manual Notes...

Page 142: ...REAR AXLE AND SUSPENSION Page M ii Repair and Service Manual Notes...

Page 152: ...SPEED CONTROL Page N ii Repair and Service Manual Notes...

Page 160: ...TROUBLESHOOTING Page P ii Repair and Service Manual Notes...

Page 168: ...WHEELS AND TIRES Page R ii Repair and Service Manual Notes...

Page 174: ...GENERAL SPECIFICATIONS Page S ii Repair and Service Manual Notes...

Page 180: ...LIMITED WARRANTY Page T ii Repair and Service Manual Notes...

Page 182: ...Page T 2 Repair and Service Manual LIMITED WARRANTY Notes...