REAR AXLE AND SUSPENSION

Page M-6

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

Tighten the hardware per torque specification table

below.

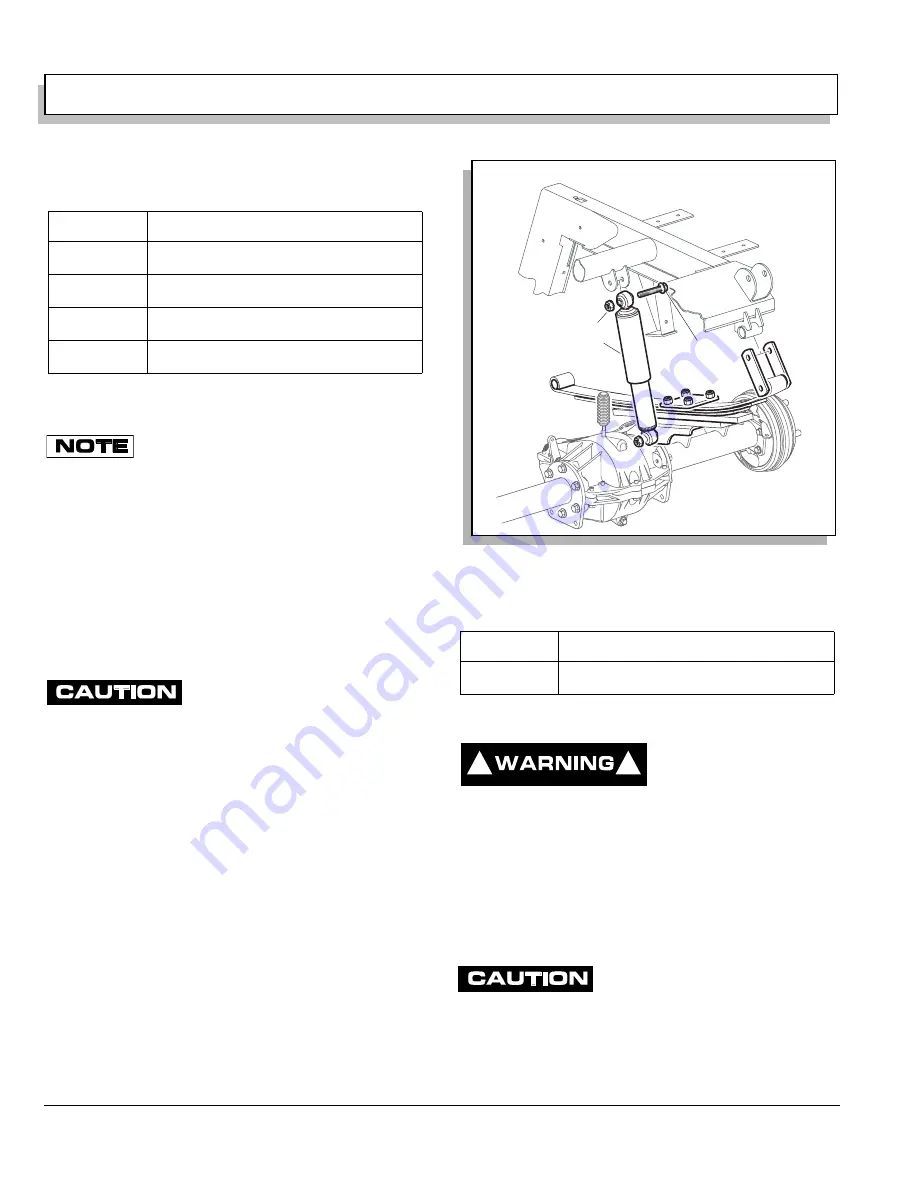

REAR SUSPENSION

In the following text, there are references to

removing/installing bolts, etc. Additional hard-

ware (nuts, washers, etc.) that are removed must always be

installed in its original positions unless otherwise specified.

Non-specified torque specifications are shown in the table con-

tained in Section A.

General

The rear suspension is the connecting member between

rear axle and main frame. It consists of the rear axle, rear

springs, shock absorbers and shock/stop mounts

mounted on to the main frame.

Shock Absorber Removal

Change the shock absorbers one at a

time.

Tool List

Qty. Required

Wheel chocks .............................................................. 4

Torque wrench, 3/8" drive, ft. lbs ................................. 1

Deep well socket, 9/16", 3/8" drive.............................. 1

Wrench, 9/16".............................................................. 1

Ball peen hammer ....................................................... 1

Park the vehicle on a flat surface. Engage park brake.

Install chocks in front and behind each rear wheel.

Release truck bed handle and lift the bed. The shock

absorber (item 3) can be accessed from the top. Hold the

bolt (item 1) using 9/16" wrench and remove lock nut

(item 2) using 9/16" socket (Ref Fig. 7 on page M-6).

Remove the shock absorber (item 3).

The installation of the shock absorber is the reverse of

disassembly using new lock nuts.

Tighten the hardware per torque specification table

below.

Rear Spring Removal

To reduce the possibility

o f personal inju ry or

death, follow the lifting

procedure in section B of this manual. Place wheel

chocks in front and behind the front wheels and

check the stability of the vehicle on the jack stands

before starting any repair procedure. Never work on a

vehicle that is supported by a jack alone.

To prevent injury caused by the broken socket, use

only socket designed for impact wrench use. Never

use a conventional socket.

When lifting the rear axle with the jack,

be sure to lift on the axle tube flanges.

NEVER lift with jack against the aluminum housing.

ITEM NO

TORQUE SPECIFICATIONS

4

11 - 14 ft. lbs (15 - 19 Nm)

8

16 - 20 ft. lbs (22 - 27 Nm)

11

21 - 25 ft. lbs (28 - 34 Nm)

13

16 - 20 ft. lbs (22 - 27 Nm)

Fig. 7 Shock Absorber Removal

ITEM NO

TORQUE SPECIFICATIONS

2

16 - 20 ft. lbs (22 - 27 Nm)

1

2

3

!

!

Summary of Contents for ST 4X4

Page 6: ...Page iv Repair and Service Manual TABLE OF CONTENTS Notes...

Page 10: ...Repair and Service Manual SAFETY INFORMATION Page viii Notes...

Page 12: ...GENERAL INFORMATION ROUTINE MAINTENANCE Page A ii Repair and Service Manual Notes...

Page 24: ...SAFETY Page B ii Repair and Service Manual Notes...

Page 34: ...BODY AND TRUCKBED Page C ii Repair and Service Manual Notes...

Page 50: ...BRAKES Page D ii Repair and Service Manual Notes...

Page 68: ...CONTINUOUSLY VARIABLE TRANSMISSION CVT Page E ii Repair and Service Manual Notes...

Page 74: ...DIRECTION AND DRIVE SELECTOR Page F ii Repair and Service Manual Notes...

Page 80: ...ELECTRICAL Page G ii Repair and Service Manual Notes...

Page 114: ...FRONT SUSPENSION AND STEERING Page J ii Repair and Service Manual Notes...

Page 128: ...FUEL SYSTEM Page K ii Repair and Service Manual Notes...

Page 136: ...PAINT Page L ii Repair and Service Manual Notes...

Page 142: ...REAR AXLE AND SUSPENSION Page M ii Repair and Service Manual Notes...

Page 152: ...SPEED CONTROL Page N ii Repair and Service Manual Notes...

Page 160: ...TROUBLESHOOTING Page P ii Repair and Service Manual Notes...

Page 168: ...WHEELS AND TIRES Page R ii Repair and Service Manual Notes...

Page 174: ...GENERAL SPECIFICATIONS Page S ii Repair and Service Manual Notes...

Page 180: ...LIMITED WARRANTY Page T ii Repair and Service Manual Notes...

Page 182: ...Page T 2 Repair and Service Manual LIMITED WARRANTY Notes...