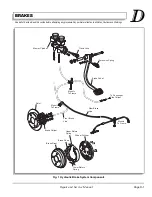

BRAKES

Page D-4

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

The hydraulic system may be checked for leaks by

applying pressure to the pedal gradually and steadily. If

the pedal sinks very slowly to the floor, the system has a

leak. This is not to be confused with a springy or spongy

feel due to the compression of air within the lines.

Check for leaks along all lines and at brake assembly. If

no external leaks are apparent, the problem is inside the

master cylinder.

After making any repairs to hydraulic lines, wheel cylin-

ders or master cylinder, the brakes must be bled to

remove any trapped air. A bleeder valve is located at

each wheel cylinder for this purpose.

MASTER CYLINDER

Just like any other brake part, the master cylinder will

eventually require replacement. The usual reason for a

master cylinder failure is the cylinder seals (cups) deteri-

orate. Fluid leaks past the cups and shows as an exter-

nal leak. A common symptom is a ‘spongy’ brake pedal

that goes all the way to the floor when all the other brake

components are in good condition. The rubber parts wear

with usage or deteriorate with age or fluid contamination.

Corrosion or deposits formed in the cylinder bore due to

moisture or dirt in the hydraulic system may result in

wear of the cylinder bore or related parts. Do not try to

remove corrosion or deposits with a cylinder hone. If cor-

rosion or deposits are present, discard master cylinder

and replace with new one.

Brake Fluid

To prevent serious per-

sonal injury or death

resulting from a battery

explosion, remove the battery. Always disconnect the

negative (-) battery cable first using insulated wrench.

To prevent serious personal injury or death resulting

from a brake system containing air, bleed the brake

system whenever the brake component is removed, a

brake line is disconnected, or the brake fluid in the

master cylinder is allowed to fall below the minimum

level and it is suspected that air may have entered the

system. Ref Bleeding And Flushing section.

During this process, it is likely that

brake fluid will leak from the master cyl-

inder. Avoid allowing brake fluid to contact the painted body

components of the vehicle. Wipe off immediately.

Hydraulic brake systems must be totally

flushed if the fluid becomes contaminated with

water, dirt or other corrosive chemicals. To flush, bleed the

entire system until all brake fluid has been replaced with fresh

DOT 3 standard automotive brake fluid.

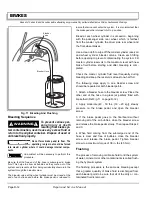

It is important to maintain proper fluid levels in the master

cylinder. The fill cap for the cylinder is located under the

cowl. To prevent contamination when checking fluid, wipe

off any dirt from fill cap before removing it. Reservoir fluid

level should be checked per ‘Periodic Service Schedule’

Section in GENERAL INFORMATION AND ROUTINE

MAINTENANCE. When required, clean brake fluid

should be added to maintain fluid level between the max-

imum and minimum level indicators of the reservoirs.

Use fresh DOT 3 standard automotive brake fluid.

Master Cylinder Replacement

To prevent serious per-

sonal injury or death

resulting from a battery

explosion, remove the battery. Always disconnect the

negative (-) battery cable first using insulated wrench.

To prevent serious personal injury or death resulting

from a brake system containing air, bleed the brake

system whenever the brake component is removed, a

brake line is disconnected, or the brake fluid in the

master cylinder is allowed to fall below the minimum

level and it is suspected that air may have entered the

system. Ref Bleeding And Flushing section.

To prevent serious personal injury or death resulting

from a brake failure resulting from contaminated

brake fluid, never reuse any excess fluid or return to

the original container. Dispose of brake fluid properly.

During this process, it is likely that

brake fluid will leak from the master cyl-

inder. Avoid allowing brake fluid to contact the painted body

components of the vehicle. Wipe off immediately.

It is recommended that brake fluid be drained

when the master cylinder is removed. Open

each bleeder valve in turn, and drain fluid into catch pan. Dis-

pose of old fluid properly.

Tool List

Qty. Required

Torque wrench, 3/8" drive, ft. lbs ................................. 1

Wrench, 3/8" ................................................................ 1

Insulated wrench, 1/2" .................................................1

Needle nose pliers .......................................................1

Shop towels ............................................................. A/R

Catch pan ....................................................................1

!

!

!

!

Summary of Contents for ST 4X4

Page 6: ...Page iv Repair and Service Manual TABLE OF CONTENTS Notes...

Page 10: ...Repair and Service Manual SAFETY INFORMATION Page viii Notes...

Page 12: ...GENERAL INFORMATION ROUTINE MAINTENANCE Page A ii Repair and Service Manual Notes...

Page 24: ...SAFETY Page B ii Repair and Service Manual Notes...

Page 34: ...BODY AND TRUCKBED Page C ii Repair and Service Manual Notes...

Page 50: ...BRAKES Page D ii Repair and Service Manual Notes...

Page 68: ...CONTINUOUSLY VARIABLE TRANSMISSION CVT Page E ii Repair and Service Manual Notes...

Page 74: ...DIRECTION AND DRIVE SELECTOR Page F ii Repair and Service Manual Notes...

Page 80: ...ELECTRICAL Page G ii Repair and Service Manual Notes...

Page 114: ...FRONT SUSPENSION AND STEERING Page J ii Repair and Service Manual Notes...

Page 128: ...FUEL SYSTEM Page K ii Repair and Service Manual Notes...

Page 136: ...PAINT Page L ii Repair and Service Manual Notes...

Page 142: ...REAR AXLE AND SUSPENSION Page M ii Repair and Service Manual Notes...

Page 152: ...SPEED CONTROL Page N ii Repair and Service Manual Notes...

Page 160: ...TROUBLESHOOTING Page P ii Repair and Service Manual Notes...

Page 168: ...WHEELS AND TIRES Page R ii Repair and Service Manual Notes...

Page 174: ...GENERAL SPECIFICATIONS Page S ii Repair and Service Manual Notes...

Page 180: ...LIMITED WARRANTY Page T ii Repair and Service Manual Notes...

Page 182: ...Page T 2 Repair and Service Manual LIMITED WARRANTY Notes...