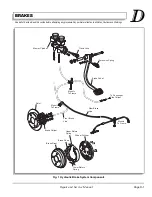

BRAKES

Page D-8

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

A backing plate assembly that shows any indication

of galling or gouging is not repairable and must be

replaced with a new wheel brake assembly. Always

replace wheel brake assemblies in pairs.

Inspect the brake drum (item 1) (Ref Fig. 5 on page D-7).

Look for a blue coloration or blistered paint that would

indicate that it has overheated. Check for evidence of

scoring/gouging. Check for excessive wear indicated by

the friction surface being significantly worn and leaving a

ledge of unworn drum. If any of these problems are

found, the drum must be replaced.

Clean the backing plate (item 16) with a commercially

available brake cleaner.

Inspect the backing plate (item 16). Inspect for gouges,

galling or other damage, particularly where the backing

plate (item 16) is contacted by the brake shoes (item 13).

Be sure shoe ledges are smooth and free of rough

edges. Replace both wheel brake assemblies (item 8) if

any gouges or galling is found.

It is normal for the shoes to show more wear at

the leading and trailing edges. If the brake

shoe thickness is approaching .06" (1.5 mm), it is recom-

mended that the shoes be replaced.

Measure the brake shoe (item 13) thickness. Measure at

the most worn area. Brake shoes must be replaced when

friction material thickness is .06" (1.5 mm) at any point on

the shoe. It is recommended that the brake shoe springs

(item 10, 11) and brake adjusters (item 17) be replaced

when installing new brake shoes.

Check springs for loss of tension and damage. Replace

weak springs and any damaged or badly worn parts.

Check adjuster (item 17) operation. Insure that each

adjuster will move with approximately 30 - 50 in. lbs (3.4 -

5.6 Nm) of torque. If adjusters are frozen, badly worn or

loose, replace the adjuster assembly.

Replace the wheel cylinder (item 14) if there is any sign

of leakage. Insure that the parking lever and strut assem-

bly moves freely. If necessary, this assembly can be ser-

viced as follows:

Disassemble by removing the C-clip. Wire brush contact

surfaces to remove any corrosion and contaminants.

Lightly grease the pin and contact surfaces before re-

assembly.

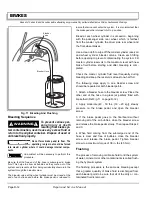

Reassembly

Apply a light coat of high temperature lubricant to shoe

support points on the backing plate (item 16), (Ref Fig. 6

on page D-8) and (Ref Fig. 5 on page D-7) to adjuster pin

(item 18), and to anchor. Position the adjusters (item 17)

so that the pins (item 18) are at the 12 o'clock position.

If the wheel cylinder (item 14) was removed, install it to

the backing plate (item 16). Insert and tighten the wheel

cylinder mounting bolts (item 15). Position shoes (item

13) on backing plate (item 16) and install hold-down

springs (item 12). Install parking brake strut with tab on

strut engaged in brake shoe web. Place upper end of

shoe webs against wheel cylinder, and install upper

shoe-to-shoe spring (item 10).

Install lower shoe-to-shoe spring (item 11).

Use great care when installing axle

shaft. The shaft must pass through an

internal oil seal.

Insert axle shaft (item 9) through brake assembly (item

8). Hold the axle and insert into axle tube (item 7). Keep

axle centered in the tube and engage it with the internal

spline within the differential. Align the four mounting

holes in the pillow block bearing with the brake assembly

mounting holes and the holes in the axle tube flange.

Install bolts (item 6) with a 1/2" socket. Connect the

brake line (item 5).

Install parking brake cable (item 4) using new cotter pins.

Pre-adjust shoes by rotating adjuster bolt (item 19) away

from the axle until shoes contact drum and then back off

just enough to eliminate drag.

Fig. 6 Backing Plate Lubrication Points

Backing Plate

Lubricate

(3) Bosses

Each Side

Lubricate

(3) Bosses

Each Side

Fixed Anchor

Wheel Cylinder

Adjuster

Adjuster Pin

Summary of Contents for ST 4X4

Page 6: ...Page iv Repair and Service Manual TABLE OF CONTENTS Notes...

Page 10: ...Repair and Service Manual SAFETY INFORMATION Page viii Notes...

Page 12: ...GENERAL INFORMATION ROUTINE MAINTENANCE Page A ii Repair and Service Manual Notes...

Page 24: ...SAFETY Page B ii Repair and Service Manual Notes...

Page 34: ...BODY AND TRUCKBED Page C ii Repair and Service Manual Notes...

Page 50: ...BRAKES Page D ii Repair and Service Manual Notes...

Page 68: ...CONTINUOUSLY VARIABLE TRANSMISSION CVT Page E ii Repair and Service Manual Notes...

Page 74: ...DIRECTION AND DRIVE SELECTOR Page F ii Repair and Service Manual Notes...

Page 80: ...ELECTRICAL Page G ii Repair and Service Manual Notes...

Page 114: ...FRONT SUSPENSION AND STEERING Page J ii Repair and Service Manual Notes...

Page 128: ...FUEL SYSTEM Page K ii Repair and Service Manual Notes...

Page 136: ...PAINT Page L ii Repair and Service Manual Notes...

Page 142: ...REAR AXLE AND SUSPENSION Page M ii Repair and Service Manual Notes...

Page 152: ...SPEED CONTROL Page N ii Repair and Service Manual Notes...

Page 160: ...TROUBLESHOOTING Page P ii Repair and Service Manual Notes...

Page 168: ...WHEELS AND TIRES Page R ii Repair and Service Manual Notes...

Page 174: ...GENERAL SPECIFICATIONS Page S ii Repair and Service Manual Notes...

Page 180: ...LIMITED WARRANTY Page T ii Repair and Service Manual Notes...

Page 182: ...Page T 2 Repair and Service Manual LIMITED WARRANTY Notes...