GX4 Manipulator 3. Environments and Installation

GX series Rev.2

31

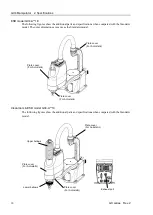

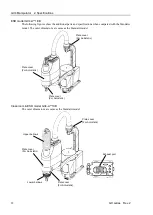

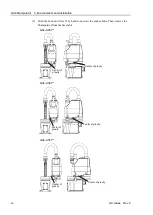

The plate for the Manipulator mounting face should be 20 mm thick or more and made

of steel to reduce vibration. The surface roughness of the steel plate should be 25

μ

m or

less.

The table must be secured on the floor or wall to prevent it from moving.

The Manipulator mounting surface should have a flatness of 0.5 mm or less and an

inclination of 0.5 ° or less to a horizontal or vertical surface. If the flatness of the

installation surface is improper, the base may be damaged or the robot may not fully

show its performance.

When using a leveler to adjust the height of the base table, use a screw with M16 diameter

or more.

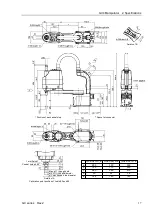

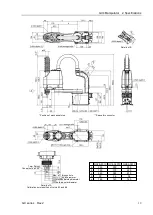

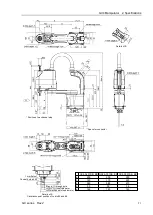

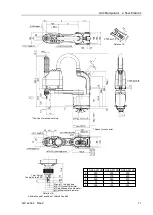

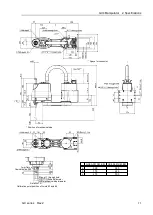

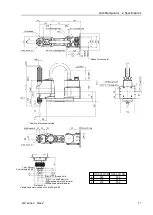

If you are passing cables through the holes on the base table, see the figures below. (unit:

mm)

M/C cable

Power connector

Signal

connector

M/C cable hood

Signal connector

54

35

49

11

82

44

Power connector

(straight)

83

76

Power connector

(L-shaped)

35

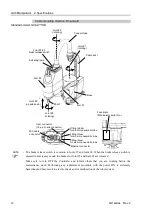

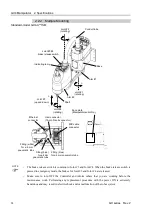

For environmental conditions regarding space when placing the Controller on the base

table, refer to the Controller manual.

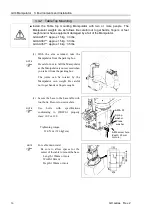

WARNING

■

To ensure safety, a safeguard must be installed for the robot system. For details

of the safeguard, refer to “

1.5 Safeguard”.

Summary of Contents for SCARA GX Series

Page 1: ...Original instructions Rev 2 EM221R5129F SCARA Robots GX series Manual ...

Page 2: ...GX series Manual Rev 2 ...

Page 12: ......

Page 86: ...GX4 Manipulator 5 Motion Range 76 GX series Rev 2 ...

Page 88: ......

Page 188: ......

Page 202: ......