GX8 Manipulator 4. Setting of End Effectors

146

GX series Rev.2

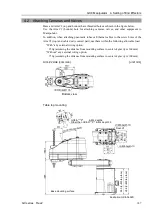

Brake release switch

- Joint #3 and Joint #4 cannot be moved up/down by

hand until the electromagnetic brake applied to the

joints have been released.

To move Joint #3 up/down or rotate Joint #4 while

attaching an end effector, turn ON the Controller

and press the brake release switch.

This button switch is a momentary-type: the brake

is released only while the button switch is being

pressed. The switch releases the brake of Joints #3

and #4 simultaneously.

Brake release switch

The shaft may be lowered

by the weight of an end

effector etc.

- Be careful of the shaft falling and rotating while the

brake release switch is being pressed because the

shaft may be lowered by the weight of an end

effector.

Layouts

- When you operate the manipulator with an end effector, the end effector may interfere

with the Manipulator because of the outer diameter of the end effector, the size of the

work piece, or the position of the arms. When designing your system layout, pay

attention to the interference area of the end effector.

Summary of Contents for SCARA GX Series

Page 1: ...Original instructions Rev 2 EM221R5129F SCARA Robots GX series Manual ...

Page 2: ...GX series Manual Rev 2 ...

Page 12: ......

Page 86: ...GX4 Manipulator 5 Motion Range 76 GX series Rev 2 ...

Page 88: ......

Page 188: ......

Page 202: ......