94

m

Drum Section

chap.2

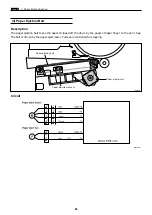

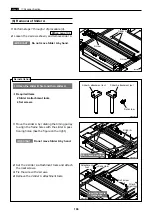

(5) Fine Start Mode

This mode automatically sets optimum values for the following start conditions: timing of ink roller actuation

during platemaking, number of no-paper rotations with the ink roller actuated.

These optimum settings are based on room temperature, the length of time the printer was out of use, and the

number of prints last time it was used. They ensure clear printing right from the first sheet after platemak-

ing.

*Room temperature of 10

;

or below can cause insufficient ink supply, even in Fine Start.

Standby state

The cam turns a half-revolution, so that the ink

roller is pressed against the drum inner surface.

Then the drum rotates.

The cam turns a half-revolution, so that the ink roller

moves out of contact with the drum inner surface.

Printing begins.

Cam

Ink

Roller

Drum

Ink roller

Squeegee

roller

Operation

R8S02087

R8S02088

R8S02089

R8S02090

Summary of Contents for DP-S Series

Page 1: ......

Page 9: ......

Page 11: ......

Page 16: ...x Dimensions chap 1 15 R8S01001 xDimensions 622 1360 510 228 1080 710 980 688 370 mm...

Page 22: ...v Part Names and Their Functions chap 1 21 44000A1e 2A 2B 2C R8S01006a 2Detailed drawing...

Page 33: ...32 z Scanner Section chap 2 Circuit R8S02E03e...

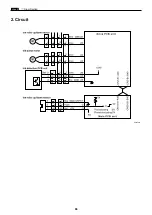

Page 87: ...86 m Drum Section chap 2 2 Circuit R8S02E30...

Page 171: ...170 MEMO...

Page 193: ...192 MEMO...

Page 195: ...194 z Help mode List chap 7 z HELP Mode List...

Page 243: ...242 c HELP Mode Function and Operation Procedures chap 7...

Page 270: ...269 c HELP Mode Function and Operation Procedures chap 7...

Page 281: ...280 MEMO...

Page 293: ...292 z Electrical Parts Layout and Their Functions chap 9 MEMO...

Page 295: ...309 294 x Overall Wiring Layout chap 9 Overall Wiring Layout 1 Main PCB 2 2...

Page 297: ...311 296 x Overall Wiring Layout chap 9 Overall Wiring Layout 2 Drive PCB 2 2...