38

x

Platemaking / Master Feed / Ejection Section

chap.2

Operation

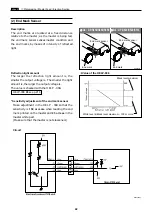

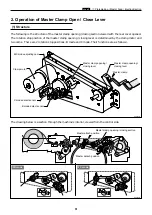

When platemaking operation starts, the drum unit

rotates to perform master removal process. The

drum which has finished master removal process

stops at the master set position.

Open the master clamp.

Sponge roller2 rotates with the master feeding

clutch ON. A certain amount of the master tip end

is fed to the master clamp section and the sponge

roller stops.

Open the master clamp

After the master clamp is closed and clamp the

master tip end, the drum rotates to roll up the

master.

When the master bottom end reaches the top of the

drum, master set is completed. Commence printing.

Master feeding clutch

Sponge roller 2

Master tip end

Master clamp

Drum

Cutter

*Check the length of the master and

drum rotation angle to control the

drum rotation.

*As the master feed clutch is OFF, the

sponge roller is free.

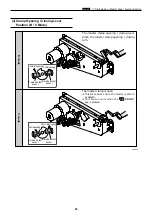

(2) Platemaking / Master Feeding

R8S02017

R8S02018

R8S02019

R8S02020

R8S02021

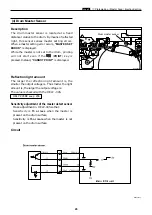

HELP-061: Platemaking is available with the

scanner opened.

NOTE :

HELP - 061

\

see p.268

Summary of Contents for DP-S Series

Page 1: ......

Page 9: ......

Page 11: ......

Page 16: ...x Dimensions chap 1 15 R8S01001 xDimensions 622 1360 510 228 1080 710 980 688 370 mm...

Page 22: ...v Part Names and Their Functions chap 1 21 44000A1e 2A 2B 2C R8S01006a 2Detailed drawing...

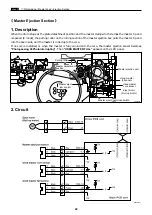

Page 33: ...32 z Scanner Section chap 2 Circuit R8S02E03e...

Page 87: ...86 m Drum Section chap 2 2 Circuit R8S02E30...

Page 171: ...170 MEMO...

Page 193: ...192 MEMO...

Page 195: ...194 z Help mode List chap 7 z HELP Mode List...

Page 243: ...242 c HELP Mode Function and Operation Procedures chap 7...

Page 270: ...269 c HELP Mode Function and Operation Procedures chap 7...

Page 281: ...280 MEMO...

Page 293: ...292 z Electrical Parts Layout and Their Functions chap 9 MEMO...

Page 295: ...309 294 x Overall Wiring Layout chap 9 Overall Wiring Layout 1 Main PCB 2 2...

Page 297: ...311 296 x Overall Wiring Layout chap 9 Overall Wiring Layout 2 Drive PCB 2 2...