z

Guaranteed Periodical Maintenance

x

Cleaning and Oiling

chap.5

168

z

Guaranteed Periodical

Maintenance

(1) Cleaning

•The serviceman will visit the user periodically after delivery. The maintenance operation described in the

periodical maintenance list

is performed and instructs how to follow the operation.

When the serviceman is called by telephone, the following maintenance must be performed after clearing

the trouble.

1. Cleaning the document.

2. Cleaning the document table glass.

3. Cleaning the thermal head.

x

Cleaning and Oiling

1.Paper shreds:

Clean with a brush or dry cloth.

Clean the mirror and reflection plate in the scanner section with a blower brush.

2.Ink:

Clean with soap.

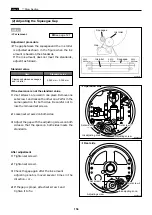

(2) Oiling

2.Gear section:

Grease the gear section after removing paper shreds on the bottom of gear.

1.Bearing section:

Oil the edge surface and bearing sections with oiler, rotating the lever and roller.

Oil or grease after ink or paper shreds are removed.

Summary of Contents for DP-S Series

Page 1: ......

Page 9: ......

Page 11: ......

Page 16: ...x Dimensions chap 1 15 R8S01001 xDimensions 622 1360 510 228 1080 710 980 688 370 mm...

Page 22: ...v Part Names and Their Functions chap 1 21 44000A1e 2A 2B 2C R8S01006a 2Detailed drawing...

Page 33: ...32 z Scanner Section chap 2 Circuit R8S02E03e...

Page 87: ...86 m Drum Section chap 2 2 Circuit R8S02E30...

Page 171: ...170 MEMO...

Page 193: ...192 MEMO...

Page 195: ...194 z Help mode List chap 7 z HELP Mode List...

Page 243: ...242 c HELP Mode Function and Operation Procedures chap 7...

Page 270: ...269 c HELP Mode Function and Operation Procedures chap 7...

Page 281: ...280 MEMO...

Page 293: ...292 z Electrical Parts Layout and Their Functions chap 9 MEMO...

Page 295: ...309 294 x Overall Wiring Layout chap 9 Overall Wiring Layout 1 Main PCB 2 2...

Page 297: ...311 296 x Overall Wiring Layout chap 9 Overall Wiring Layout 2 Drive PCB 2 2...