Continued

Cable Connections

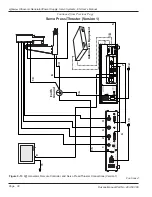

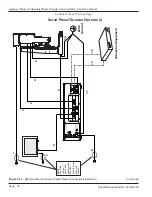

The

iQ

Servo Presses are configured in one of two ways,

depending on the model.

E

ach has unique cabling require-

ments.

Version 1- Remote Controller

Configuration

(Press Models: 43S215, 43S245-AX)

Typical Components:

•

iQ

Generator

• iQ

Servo Press

•

Remote Controller (contains servo electronics)

•

HMI Interface (optional on some systems)

•

Customer Automation Equipment

Connect the Cables

Use the following references as guides to making the

connections:

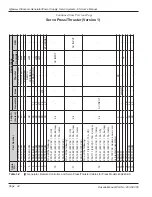

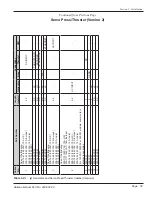

For press model 43S215, use Figure 3-13 and Table

3-IV.

For press models 43S245-AX, use Figure 3-13 and

Table 3-V.

1. Make the basic cable connections

1

through

9

, and

13-16

.

2. Make any optional connections.

3. Connect any customer-supplied equipment such as

automation. Use cables

17

and

18

for automation.

4. Connect customer-supplied electricity using cables

10

,

11

, and

12

.

Connect the power cords last, but do not turn on the

power yet.

5. Recheck all connections. When they are secure, you

are ready to connect electrical power.

6. Finally, connect electrical power. See

Section 11,

Specifications

for AC power requirements.

Before connecting or

disconnecting cables:

Put power switches for

the

iQ

generator, press,

remote controller, and any user-

supplied automation equipment in

the OFF position. Turn off electrical

power. Remove AC power cords

from their receptacles.

CAUTION

DO NOT

operate the

generator unless the

ultrasound coaxial ca-

ble is connected and

the transducer is installed in the

thruster. Otherwise, an overload

condition could occur, with pos-

sible damage to the generator.

CAUTION

NOTE

Some connectors have a pair of

threaded jack screws to secure the

connector. Make sure the screws are

snug, but do not overtighten them.

Page 29

Dukane Manual Part No. 403-587-00

Section 3 - Installation