AC Power Inlet Panel

The standard AC power inlet panel is described in this sec-

tion.

IEC AC Power Inlet Connector

The IEC AC power inlet connector mounted on the system

AC power inlet panel requires a properly configured IEC

compliant power cord, which enables worldwide system

operation by simply changing the power cord.

Low profile systems are equipped with a 10 amp rated IEC

inlet connector. The high profile systems include a 16/20

amp rated IEC inlet connector. 120VAC and 3600/4800W

systems include a non-detachable power cord.

An appropriately rated power cord must be securely at-

tached to the welding system’s IEC inlet connector. If the

correct power cord configuration is not included with the

system for the local AC power outlet at your location, an

appropriate IEC power cord should be available from a

local electrical parts supplier. Note that the system under-

voltage lockout will inhibit system operation if a North

American power cord configured for 120V is connected to

the system. A minimum of 180V is required for the system

to operate.

Fixed AC Power Cords

For some models an appropriately rated AC power cord is

permanently mounted to the power inlet panel.

Power Switch/Circuit Breaker

The power switch/circuit breaker has a rocker type actua-

tor switch that will activate or deactivate the AC power

to the system. The power ON position is marked with the

internationally recognized I symbol, the power OFF posi-

tion is marked with the 0 symbol. This power switch also

integrates an appropriately sized over-current protection

circuit breaker function in the generator.

If an over-current condition trips the circuit breaker, it will

automatically switch to the OFF position. If the overload

current that caused the circuit breaker to trip is due to a

transient condition, the circuit breaker can be reset by

switching the actuator back to the ON position. If when

resetting the circuit breaker after it has tripped, it imme-

diately trips again, there is likely an internal system mal-

function, and the generator will require service.

Do not repeatedly try to reset the circuit breaker. If it trips,

this will only cause more damage to the generator.

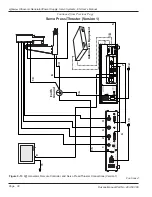

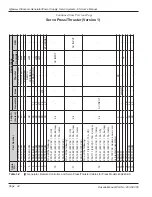

System I/O Panel

The standard system I/O panel is described in this sec-

tion. See Figure 3-6 on the next page.

System Inputs Connector

The

SYSTEM INPUTS

connector mounted on the sys-

tem I/O panel includes connections for all of the basic

system control input signals, that will typically come

from an automated control system. The cable attached to

this connector includes all of the available system con-

trol signals, which will be controlled by an output card

or output port on the automation controller.

The user can determine which signals to use for each

particular welding application, but there must be at least

one connection to this connector in order to activate the

ultrasound output. All of the input signals on this connec-

tor are electrically isolated (signals are NOT referenced

to chassis ground) and activated when a 24VDC voltage

source is connected to the signal input pin, referenced

to the isolated common pin. The electrically isolated in-

put signals can be driven from an automation controller

output that is either sinking (NPN) or sourcing (PNP),

depending upon how the isolated common connection

is terminated. All inputs sink or source 10mA of current

from a 24VDC power supply.

Chassis Grounding Stud

The chassis grounding stud is used to attach a protec-

tive earth ground to the generator. This will aid in the

suppression of electrical interference or radio frequency

interference (RFI) that is common in a industrial envi-

ronment. The chassis ground stud is

C

in Figure 3-5.

Proper system grounding is discussed on Page 9.

Figure 3-5

IEC AC Power Inlet Connector

LINE VOLTAGE:

200-240 Vac

50/60Hz, 10A

PE

I

0

-WARNING-

DUKANE CORP.

POWER LINE OUTLET

MUST BE GROUNDED

DISCONNECT LINE POWER

BEFORE REMOVING COVER

ST. CHARLES IL. 60174

MADE IN U.S.A.

UL: 1012:2010

CSA: C22.2 61010-1-12

IEC: 61010-2012

C

US

U.S. PATENTS 7,475,801

7,819,158 AND 7,225,965

C

Continued

Page 17

Dukane Manual Part No. 403-587-00

Section 3 - Installation