Chapter 14

14-1

14.1 Scanning System

14.1.1 Procedure after Replacing the Copyboard Glass

0020-1580

After replacing the copyboard glass, enter the correction values (X, Y, Z) of

the standard white plate which are indicated on the back of the new copy-

board glass in the service mode.

Correction value (X):

Service mode> COPIER> ADJUST> CCD> W-PLT-X

Correction value (Y):

Service mode> COPIER> ADJUST> CCD> W-PLT-Y

Correction value (Z):

Service mode> COPIER> ADJUST> CCD> W-PLT-Z

Also, rewrite the values in the service book.

F-14-1

14.1.2 Procedure after Replacing the Reader Unit

0020-4991

After replacing the reader unit, execute automatic detection of the CCD read-

ing position at ADF stream reading in the following service mode.

COPIER> FUNCTION> INSTALL> STRD-POS

[Operation]

Adjust the reading position by moving the scanner in increments of 0.1

mm.

[Time]

When the lamp is turned on: Adjustment time; 10 seconds

When the lamp is not turned on: Lamp adjustment time; 10 to 30 seconds

+ Adjustment time; 10 seconds

14.2 Fixing System

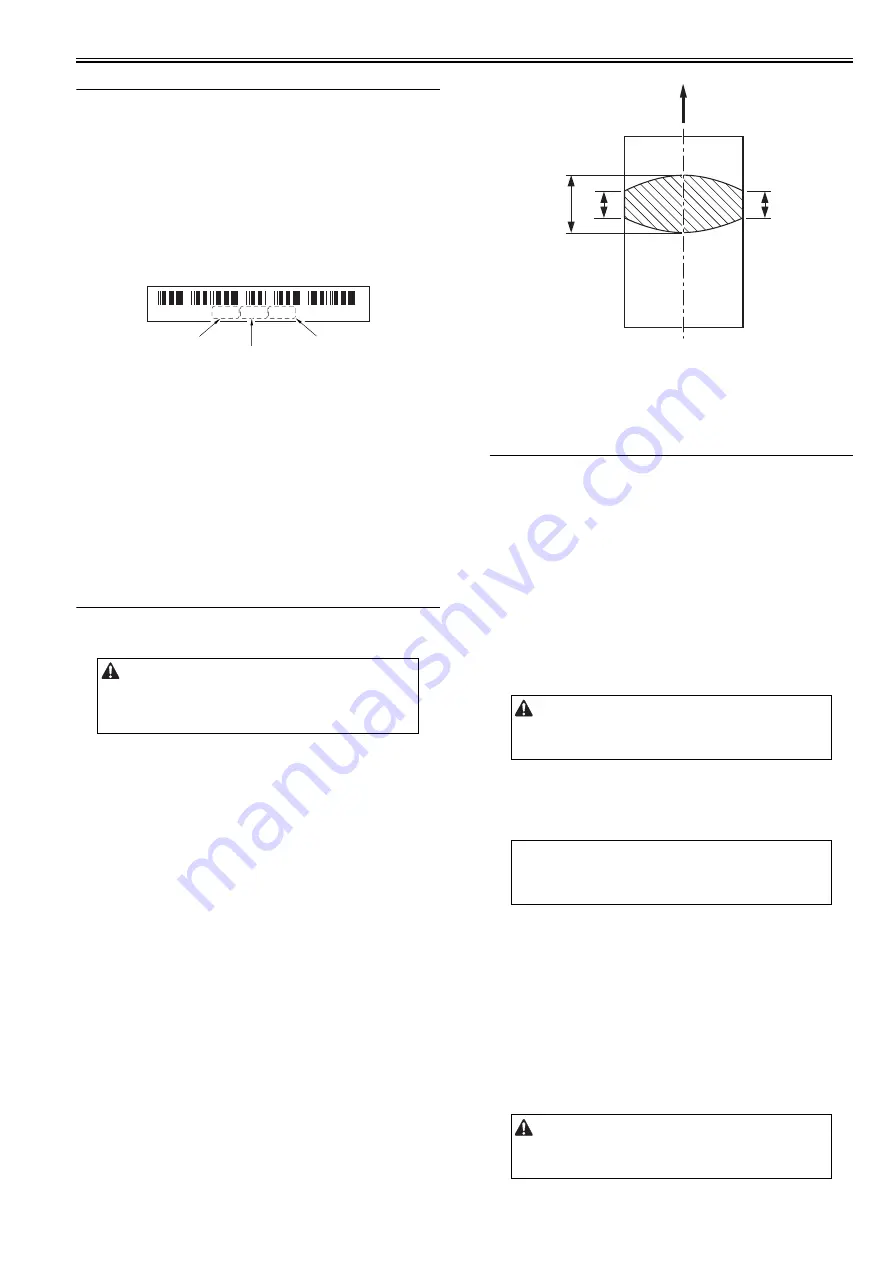

14.2.1 Checking the Nip Width (fixing pressure roller)

0019-5106

An incorrect nip width may cause the faulty fixing.

Check the nip width by following the procedure below if poor fixing image

defect occurs.

1) Make an all solid black print of A4 or Letter size using an toner cartridge

same as for this machine, and take the print to the customer's site.

2) Place the solid black print, with the printed side facing DOWN, in the cas-

sette of the printer.

3) Press the test print switch.

4) Open the upper cover as soon as the leading edge of the paper appears in

the delivery slot. Leave it for ten seconds.

5) Turn OFF the machine and take fixing unit from the machine. Then take

the paper out from the fixing unit.

6) Measure the width of the glossy band across the paper and check that it

meets the requirements as shown in Figure.

- Center (a): 8 +/- 1.0 mm

- Difference between right/left and center (a-b, a-c): 0 to 1 mm

- Difference between right and left (|b-c|): 1.5 mm or less

F-14-2

Replace the fixing unit if the nip width is out of specification, since the nip

width of the fixing unit is not adjustable in this machine.

14.3 Electrical Components

14.3.1 Procedure after Replacing the DC controller PCB

0019-8983

After replacing the DC controller PCB, restore the backup data from the

main controller PCB.

1) Using the service mode, restore the backup data of the DC controller

stored in NVRAM of the main controller PCB to NVRAM of the DC con-

troller PCB.

COPIER> FUNCTION> VIFFNC> RSTR-DCN

2) Execute "Initial Setting/Registration > Adjustment/Cleaning > Automatic

Gradation Correction > Full Correction".

14.3.2 Procedure after Replacing the Main Controller PCB

0019-8984

After replacing the main controller PCB with new one, perform the follow-

ing procedure.

1. Backup the user data

Import the user data using the remote UI.

2. Enter the flicker adjustment value of the control panel

1) Using the service mode, check the flicker value of the control panel.

TESTMODE> PANEL> FLICKER CHECK START> FLICKER AD-

JUST

2) Replace the main controller PCB.

3) Using the service mode, enter the adjustment value checked in Step 1).

TESTMODE> PANEL> FLICKER CHECK START> FLICKER AD-

JUST

4) Using the user mode, execute automatic gradation correction (full correc-

tion).

Initial Setting/Registration> Adjustment/Cleaning> Automatic Gradation

Correction> Full Correction

14.3.3 Procedure after Clearing RAM Data

0020-1581

After clearing the RAM data (ALL CLEAR) in the main controller PCB, per-

form the following procedure.

1. Backup the user data

Import the user data using the remote UI.

When removing a paper, be sure to turn on the power supply and remove it

after checking that jam has occurred in the machine.

Take notice that removing a paper with no jam occurred in the machine may

cause a broken fixing film.

* 8 2 0 6 8 6 6 7 9 3 4 9 *

correction

value (X)

correction

value (Y)

correction

value (Z)

The machine does not support "Import/export via USB" (provided in the

following service SW) because it supports network as standard function.

# COPIER->FUNCTION->PARAM->SYS-SW->Bit Switch->SW 02 Bit6

MEMO:

The flicker adjustment value can be also checked in the spec list (FLICKER

ADJ PRM).

How to output the spec list: COPIER> FUNCTION> MISC-P> OUTPUT>

SPEC

The machine does not support "Import/export via USB" (provided in the

following service SW) because it supports network as standard function.

# COPIER->FUNCTION->PARAM->SYS-SW->Bit Switch->SW 02 Bit6

Feed direction

c

a

b

Center of A4 or Letter sized paper

Summary of Contents for iR C1020 Series

Page 1: ...Sep 8 2008 Service Manual iR C1020 Series iR C1021i ...

Page 2: ......

Page 6: ......

Page 18: ...Contents ...

Page 19: ...Chapter 1 Introduction ...

Page 20: ......

Page 22: ......

Page 57: ...Chapter 2 Installation ...

Page 58: ......

Page 60: ......

Page 73: ...Chapter 3 Basic Operation ...

Page 74: ......

Page 76: ......

Page 81: ...Chapter 4 Main Controller ...

Page 82: ......

Page 84: ......

Page 97: ...Chapter 5 Original Exposure System ...

Page 98: ......

Page 100: ......

Page 112: ......

Page 113: ...Chapter 6 Original Feeding System ...

Page 114: ......

Page 116: ......

Page 132: ......

Page 133: ...Chapter 7 Laser Exposure ...

Page 134: ......

Page 136: ......

Page 143: ...Chapter 8 Image Formation ...

Page 144: ......

Page 146: ......

Page 180: ......

Page 181: ...Chapter 9 Pickup and Feed System ...

Page 182: ......

Page 213: ...Chapter 9 9 29 F 9 79 1 2 3 ...

Page 214: ......

Page 215: ...Chapter 10 Fixing System ...

Page 216: ......

Page 218: ......

Page 233: ...Chapter 11 External and Controls ...

Page 234: ......

Page 263: ...Chapter 12 e maintenance imageWARE Remote ...

Page 264: ......

Page 266: ......

Page 275: ...Chapter 12 12 9 F 12 27 ...

Page 280: ......

Page 281: ...Chapter 13 Maintenance and Inspection ...

Page 282: ......

Page 284: ......

Page 286: ......

Page 287: ...Chapter 14 Measurement and Adjustments ...

Page 288: ......

Page 290: ......

Page 293: ...Chapter 15 Correcting Faulty Images ...

Page 294: ......

Page 296: ......

Page 317: ...Chapter 16 Error Code ...

Page 318: ......

Page 320: ......

Page 331: ...Chapter 16 16 11 ...

Page 332: ......

Page 333: ...Chapter 17 Special Management Mode ...

Page 334: ......

Page 336: ......

Page 343: ...Chapter 17 17 7 ...

Page 344: ......

Page 345: ...Chapter 18 Service Mode ...

Page 346: ......

Page 348: ......

Page 388: ......

Page 389: ...Chapter 19 Upgrading ...

Page 390: ......

Page 392: ......

Page 396: ...Chapter 19 19 4 3 Click Next F 19 4 4 Select a USB connected device and click Next F 19 5 ...

Page 397: ...Chapter 19 19 5 5 Click Start F 19 6 6 Click Yes F 19 7 Download will be started F 19 8 ...

Page 399: ...Chapter 19 19 7 ...

Page 400: ......

Page 401: ...Chapter 20 Service Tools ...

Page 402: ......

Page 404: ......

Page 407: ...Sep 8 2008 ...

Page 408: ......