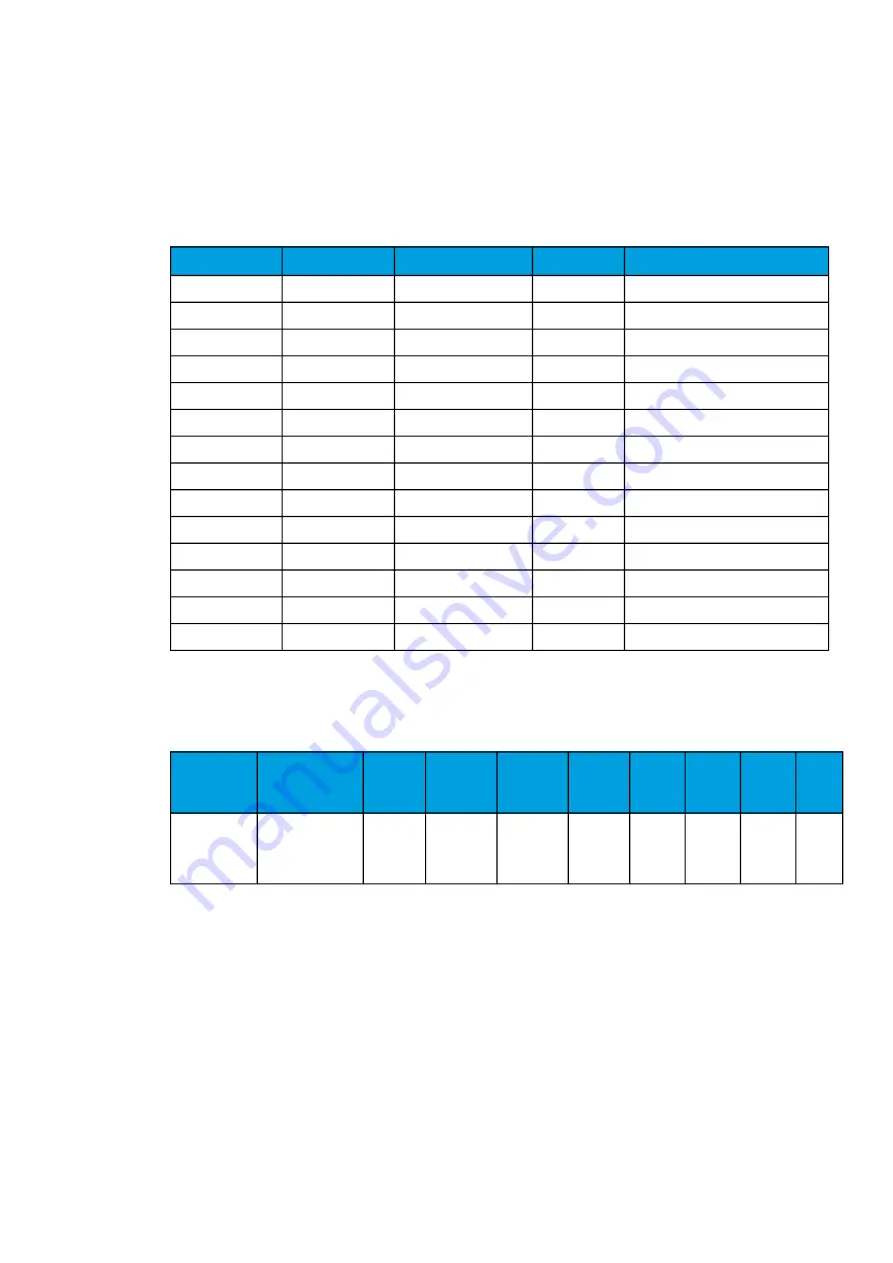

Events and registers

The motor start/locked rotor monitoring function (abbreviated "LCR" in event block names) generates

events from the detected motor status. The data register is available, based on the changes in the

events.

Table. 5.3.20 - 161. Event codes.

Event number

Event channel

Event block name

Event code

Description

3648

57

LCR1

0

Max. Start time exceed ON

3649

57

LCR1

1

Max. Start time exceed OFF

3650

57

LCR1

2

Set start time exceed ON

3651

57

LCR1

3

Set start time exceed OFF

3652

57

LCR1

4

Speed Switch not received ON

3653

57

LCR1

5

Speed Switch not received OFF

3654

57

LCR1

6

Start ON

3655

57

LCR1

7

Start OFF

3656

57

LCR1

8

Set time Trip ON

3657

57

LCR1

9

Set time Trip OFF

3658

57

LCR1

10

Max cap Trip ON

3659

57

LCR1

11

Max cap Trip OFF

3660

57

LCR1

12

Blocked ON

3661

57

LCR1

13

Blocked OFF

The function registers its operation into the last twelve (12) time-stamped registers. The table below

presents the structure of the function's register content.

Table. 5.3.20 - 162. Register content.

Date and

time

Event

code

Start

stall

time

Max. time

used

Set time

used

Thermal

cap.

used

L1

current

L2

current

L3

current

SG

used

dd.mm.yyyy

hh:mm:ss.mss 3648-3661 Descr.

Recorded

duration

of stall/

start

Percentage

used from

max safe

stall time

Percentage

used from

user set

max time

Thermal

capacity

used

Phase

L1

current

x I

n

Phase

L2

current

x I

n

Phase

L3

current

x I

n

Used

setting

group

5.3.21 Frequent start protection (N>; 66)

The frequent start protection function is used for monitoring and preventing the starting of the motor to

happen too frequently. This function monitors the number of the starts the motor has used within a

given time frame to ensure that the start stress does not exceed the limits stated by the manufacturer.

The start-up situation is most stressful normal operation situation for motors that are started with Direct

On Line; the manufacturer gives safe start limits with a specified time frame for both cold and hot

motors in order to guarantee the motor's lifetime. Usually the manufacturers also specify the time

between consequent starts. When a set number of starts have been used or a new start or start

attempt is made too quickly after the previous start or start attempt, further starting attempts should be

blocked by using the N> function, thus allowing the motor to cool down sufficiently before the next start

attempt.

A

AQ

Q-M215

-M215

Instruction manual

Version: 2.04

234