00-5 Precautions:

• Before measuring voltage at each terminal, check to

make sure that battery voltage is 11 V or higher.

Terminal voltage check with a low battery voltage will

lead to erroneous diagnosis.

• Never connect any tester (voltmeter, ohmmeter, or

whatever) to the electronic unit when its coupler is

disconnected. Otherwise, damage to electronic unit

may result.

• Never connect an ohmmeter to the ECM with its

coupler connected. If attempted, damage to ECM or

sensors may result.

• Be sure to use a specified voltmeter/ohmmeter.

Otherwise, accurate measurements may not be

obtained and personal injury may result.

Electrical Circuit Inspection Procedure

While there are various methods for electrical circuit

inspection, described here is a general method to check

for open and short circuit using an ohmmeter and a

voltmeter.

Open circuit check

Possible causes for the open circuit are as follows. As

the cause can exist in the connector/coupler or terminal,

they need to be checked carefully.

• Loose connection of connector/coupler

• Poor contact of terminal (due to dirt, corrosion or rust,

poor contact tension, entry of foreign object etc.)

• Wire harness being open.

• Poor terminal-to-wire connection.

When checking system circuits including an electronic

control unit such as ECM, etc., it is important to perform

careful check, starting with items which are easier to

check.

1) Disconnect the negative (–) cable from the battery.

2) Check each connector/coupler at both ends of the

circuit being checked for loose connection. Also

check for condition of the coupler lock if equipped.

3) Using a test male terminal, check the female

terminals of the circuit being checked for contact

tension.

Check each terminal visually for poor contact

(possibly caused by dirt, corrosion, rust, entry of

foreign object, etc.). At the same time, check to

make sure that each terminal is fully inserted in the

coupler and locked.

If contact tension is not enough, rectify the contact to

increase tension or replace. The terminals must be

clean and free of any foreign material which could

impede proper terminal contact.

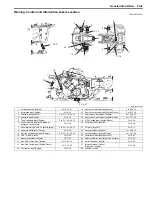

I310G1000012-02

1. Sensor

“A”: Check for loose connection

“B”: Check contact tension by inserting and removing.

“C”: Check each terminal for bend and proper alignment.

ECM

“A”

1

“A”

I718H1000005-02

“C”

“B”

I649G1000027-02

Содержание 2009 LT-A500XP

Страница 2: ......

Страница 4: ......

Страница 14: ...00 9 Precautions ...

Страница 224: ...1E 3 Engine Lubrication System EXHAUST SIDE INTAKE SIDE I931H1150003 02 ...

Страница 304: ...1K 4 Exhaust System ...

Страница 346: ...2D 5 Wheels and Tires ...

Страница 438: ...3D 26 Propeller Shafts ...

Страница 482: ...4D 6 Parking Brake ...

Страница 512: ...5A 28 Automatic Transmission ...

Страница 582: ...9 ii Table of Contents Specifications 9E 7 Tightening Torque Specifications 9E 7 Special Tools and Equipment 9E 7 ...

Страница 624: ...Prepared by December 2008 Part No 99500 44080 03E Printed in U S A 624 ...