3-44

3

Operation Examples (Position correction)

1

2

F C1 H

[OBJECT TYPE COND]

1

OBJECT TYPE NO.

00(0~15)

2

EDIT

COPY(

←OBJ

TYPE00) INITIALIZE

3

TITLE REGISTRATION (TO NEXT SUB-MENU)

4

MEAS.0, CAMERA1

NO (TO NEXT SUB-MENU)

5

POS. ADJ.CAMERA1

NO ADJ. [REG. 0-1PNTSXY]

6

MEAS.0, CAMERA2

NO (TO NEXT SUB-MENU)

7

POS. ADJ.CAMERA2

NO ADJ. [REG. 0-1PNTSXY]

8

SELECT CAMERA IMG NO CAM1 CAM1 CAM1&2

0

MEASUREMENT 1

NO (TO NEXT SUB-MENU)

q

MEASUREMENT 2

NO (TO NEXT SUB-MENU)

w

MEASUREMENT 3

NO (TO NEXT SUB-MENU)

e

FINAL CALC RESULT

(TO NEXT SUB-MENU)

r

FINAL OUTPUT COND (TO NEXT SUB-MENU)

t

SYSTEM-IN/OUT

(TO NEXT SUB-MENU)

y

HALT MEAS ON NG

NO

YES

u

UPPER MENU

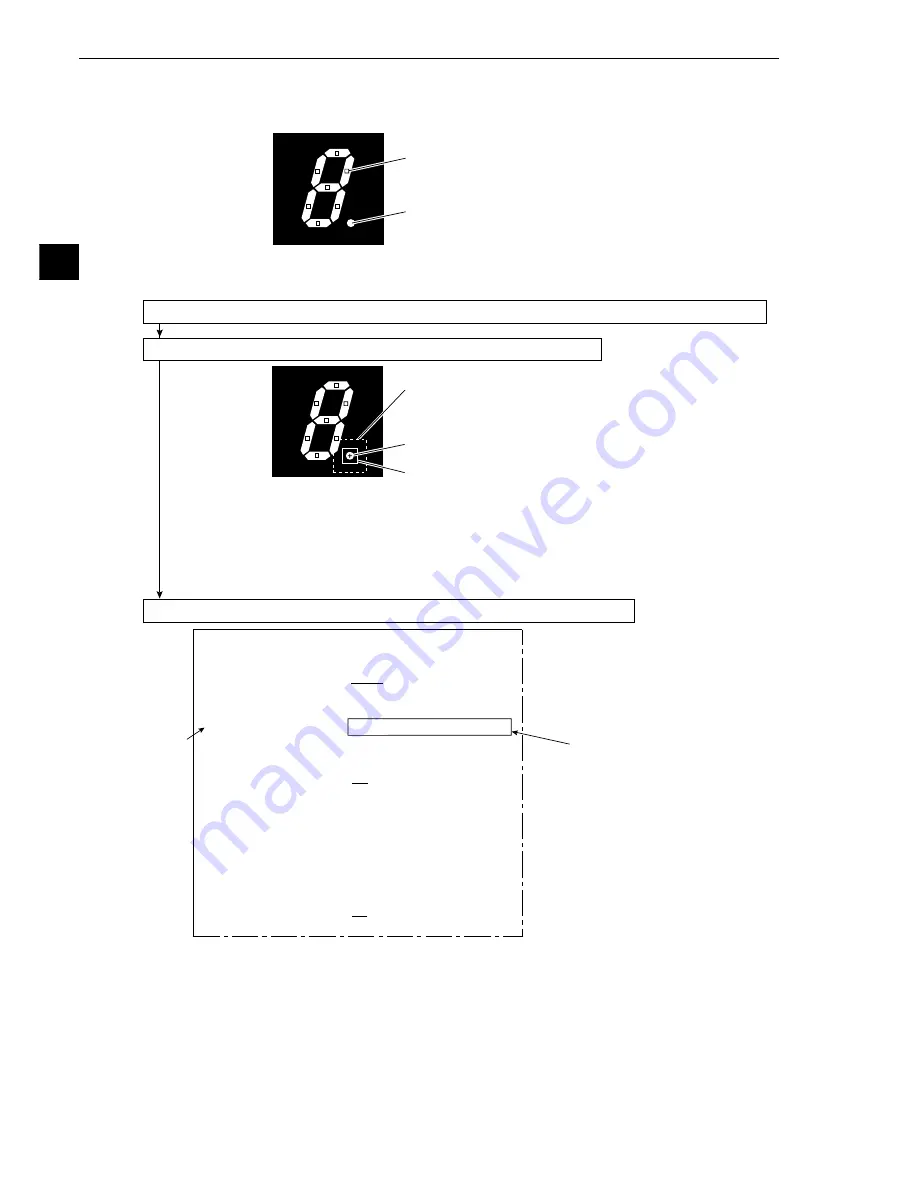

Point setting

Decimal point

Search window

Decimal point (positioning mark)

Image window

3-7 Position correction (example of point measurement)

In the setting example shown in section 3-6 "Existence inspection by point measurement," points were set

on the segment of number display (the object to be measured), and the each of the points was checked for

the correct condition.

However, the object to be measured is not always located exactly at the preset points. To deal with this

problem, use the position correction function. Then, the preset coordinates of the points are corrected

according to positional deviation of the actual object, and the measurement can be carried out correctly.

(1) Set the points using item (1) to (10) in section 3-6 "Existence inspection by point measurement"

(2) Using the decimal point in a 7-segment display as a positioning mark

- Move the reference point as described in items (1) to (10), in section 3-2 "Position

measurement."

After the setting, move the cursor to [SET-SCRN] on the MAIN OPS MENU, and press the

SET key.

-

The [SYSTEM SETUP] menu will be displayed. Move the cursor to

2

OBJECT TYPE

COND (conditions of object type) and press the SET key.

-

The [OBJECT TYPE COND] menu will be displayed.

(3) Operation on the [OBJECT TYPE COND] (conditions of object type) menu

1. Move the cursor to

5

POS. ADJ.CAMERA1 (position correction) with the up and down keys,

and press the SET key.

2. Move the cursor to REG.0-1PNTSXY (registration: 0-1, first point: XY) with the right, left, up

and down keys, and press the SET key. (Correction of X-Y coordinates).

3. Move the cursor to

u

UPPER MENU with the up and down keys, and press the SET key.

-

The [SYSTEM SETUP] menu will be displayed. Move the cursor to

0

OPERATIONS with

the up and down keys, and press the SET key.

-

The MAIN OPS MENU will be displayed.

This completes the settings for position correction using a deviation measurement. Run the

program, and the preset point coordinates will be moved according to the actual position of the

decimal point. Then the point inspection will be conducted.