Содержание Avalon FM20

Страница 2: ......

Страница 6: ...6 ...

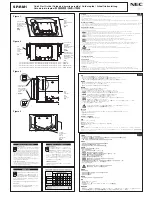

Страница 38: ...3 Installation Instructions 38 ...

Страница 46: ...4 Theory of Operation 46 ...

Страница 145: ...10 Repair and Disassembly 145 7 The top cover assembly is now separated from the bottom housing assembly ...

Страница 154: ...10 Repair and Disassembly 154 10 Take the new rear housing cover and place it in the position shown ...

Страница 155: ...10 Repair and Disassembly 155 11 Put the two halves of the display assembly together as shown ...

Страница 163: ...10 Repair and Disassembly 163 4 Turn over the top cover assembly and place it top down on a cloth or other soft surface ...

Страница 167: ...10 Repair and Disassembly 167 10 Remove the four screws holding the recorder chassis ...

Страница 169: ...10 Repair and Disassembly 169 12 Remove the RFI bracket 13 Lift out the recorder chassis ...

Страница 200: ...10 Repair and Disassembly 200 2 Remove the screws holding the metal shield 3 Remove the shield ...

Страница 254: ...12 Specifications 254 ...

Страница 259: ......

Страница 260: ...Part Number 453564541271 Published in Germany 11 14 453564541271 ...