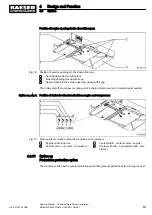

Connecting the battery jumper cables:

1. Clamp the first terminal clamp

3

of the red jumper cable to the positive pole of the machine's

battery.

2. Clamp the second terminal clamp

2

of the red jumper cable to the positive pole of the assist‐

ing vehicle's battery.

3.

Explosion hazard!

A spark may ignite an explosive gas mixture.

➤ Do not, under any circumstances, connect the negative pole of the assisting machine to

the negative pole of the battery in the machine to be jump-started.

Sparks may be caused when connecting and disconnecting.

➤ Work with caution.

4. Connect the first pole clamp

4

of the black jumper cable to the engine block or a connected,

solid and unpainted metal component of the machine

5

(as distant as possible to the battery).

5. Clamp the second terminal clamp

1

of the black jumper cable to the negative pole of the as‐

sisting vehicle's battery.

Starting the engine:

1. Start the engine of the assisting vehicle and run at high speed.

2. Start the compressor engine.

Upon a successful start, run both engines run for approximately 10 - 15 minutes.

This is important, in particular for fully discharged batteries. In the beginning, they will only

pick up little current and have a high internal resistance. Any voltage peaks occurring in the

engine generator in this state can be attenuated only by the batteries of the assisting vehicle.

In particular the engine electronics of the machine are sensitive to overvoltages and could be

damaged easily.

Disconnecting the battery jumper cables:

1. Stop the engine of the assisting vehicle.

2. Disconnect the jumper cables in the reverse order, first negative (-) then positive (+) poles.

3. Replace the pole caps.

4. Close the maintenance panels and/or bonnet.

If the compressor engine stops as soon as the cables are disconnected, this could indicate

major damage (e.g., to the engine generator or batteries) which must be repaired by a speci‐

alised workshop.

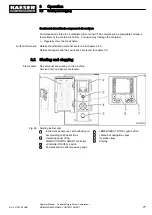

7.4.2 Option ba

Starting up low-temperature equipment

Starting the engine coolant pre-heating:

The engine coolant can be pre-heated to improve starting under cold conditions.

➤ Start the coolant pre-heating as described in chapter 7.5.

7

Initial Start-up

7.4

Low-temperature operation (winter)

72

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M82 SIGMA CONTROL SMART

No.: 901783 08 USE

Option bb