Points to be observed with separate compressed air lines:

Lubrication with tool oil.

Air tools that must not be lubricated can be damaged.

➤ Blow any residual oil out of the line before connecting such an air tool.

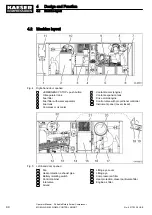

4.8.2 Option bb; od

Auxiliary electrical systems

The following auxiliary electrical equipment is provided in the machine:

■ Coolant pre-heating for diesel engine

■ Battery charger for automatic start/stop

The auxiliary electrical equipment is pre-wired for operation. A separate mains power connection

provides power.

A flexible power cable (supplied) connects the machine's power plug to the user's power socket.

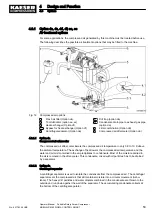

Coolant pre-heating for diesel engine:

The engine's coolant should be pre-heated in order to protect the engine at low temperatures. A

coolant pre-heating system is installed for this purpose. The coolant pre-heating works according to

the principle of self-circulation.

Battery charger for automatic start/stop:

The start/stop automatism can be set in the SIGMA CONTROL SMART controller for automatic

machine start. The engine's starting battery must be sufficiently charged at any time, in order for

the drive engine to be started even after longer standstill times. Use a battery charger.

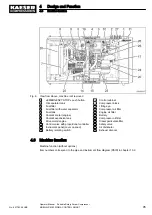

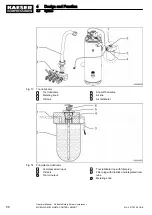

4.8.3 Option ba

Low temperature equipment options

Special equipment is provided for operation in extremely low temperatures.

This equipment assures trouble-free operation in ambient temperatures from -13°F to 122°F.

The electrical system will reliably start the engine at ambient temperatures to -4°F.

Coolant pre-heating:

The engine coolant can be pre-heated to improve starting under cold conditions.

The ideal coolant pre-heating period is 2-3 hours before the machine is started. A pre-heating peri‐

od of more than 3 hours is not necessary, as the maximum effect has already been achieved within

this period (thermal balance).

Continuous operation of maximum 6 hours must be followed by a rest period of approximately

3 hours.

4

Design and Function

4.8

Options

No.: 901783 08 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M82 SIGMA CONTROL SMART

57

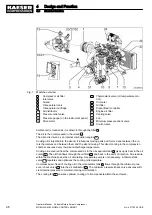

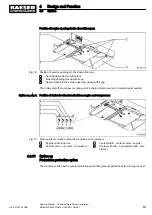

Option fc

Option bb

Option od

Option bb