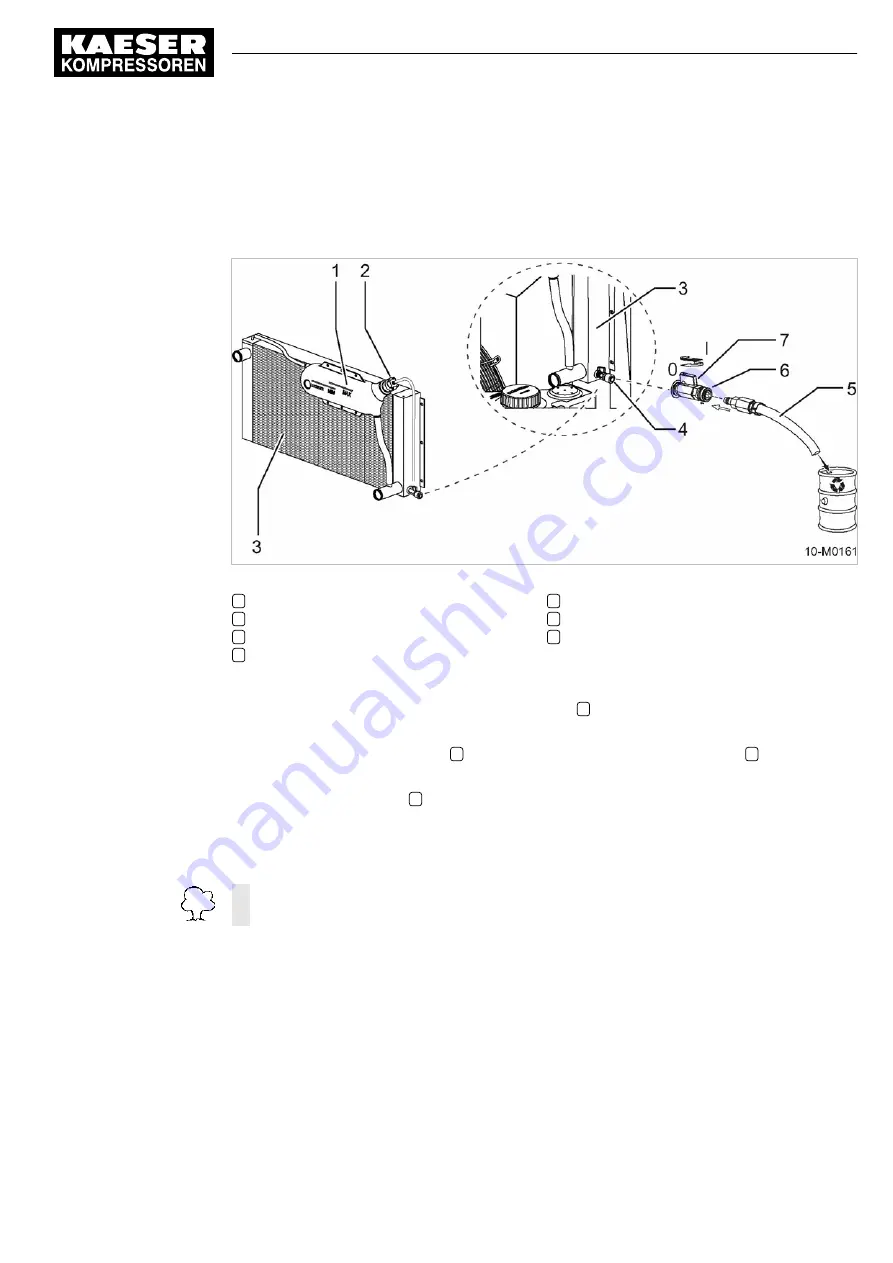

Draining the coolant (machine with chassis):

In machines with chassis (no closed floor pan, no stationary machine), the entire coolant of the

cooling circuit is drained directly at the engine's coolant cooler. Draining is carried out via a shut-off

valve by means of a separate drain hose.

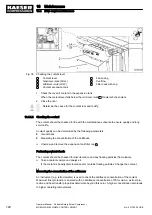

Fig. 40 Draining the coolant from the engine coolant cooler

1

Coolant expansion tank

2

Filler cap

3

Coolant cooler

4

Coolant drain

5

Drain hose with male fitting

6

Quick-release coupling

7

Shut-off valve (ball valve)

I - Open

0 - Closed

1. Unscrew and remove the expansion tank filler cap

2

.

2. Position a collecting vessel beneath the water cooler drain point (hole in the floor panel).

3. Connect a suitable drain hose

5

to the coolant cooler quick-release coupling

6

.

4. Place the free end of the hose in the receptacle and secure.

5. Open the shut-off valve

7

and catch the draining coolant.

6. Close the shut-off valve and remove the drain hose.

7. Screw on the filler cap.

8. Close the door.

➤ Dispose of used coolant in accordance with environmental protection regulations.

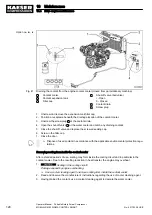

Draining the coolant (closed floor pan/stationary machine):

On stationary machines and machines with closed floor pan, lines draining oil and coolant from the

motor and compressor are led to a central point outside the machine. The coolant is drained via a

pipe which is screwed into the drain opening of the cooler and closed with a shut-off valve. The

pipe is sealed with a screw plug at the drain end.

10 Maintenance

10.4 Drive engine maintenance

No.: 901783 08 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M82 SIGMA CONTROL SMART

123

Option oe, rw, rx