Miscellaneous functions for path behavior

10.4

10

HEIDENHAIN | TNC 620 | ISO Programming User's Manual | 9/2016

397

Calculating the radius-compensated path in advance

(LOOK AHEAD): M120 (Miscellaneous Functions

software option)

Standard behavior

If the tool radius is larger than the contour step that is to be

machined with radius compensation, the TNC interrupts program

run and generates an error message. M97” suppresses the error

message, but it results in dwell marks and will also move the

corner.

"Machining small contour steps: M97",

If the programmed contour contains undercut features, the tool

may damage the contour.

Behavior with M120

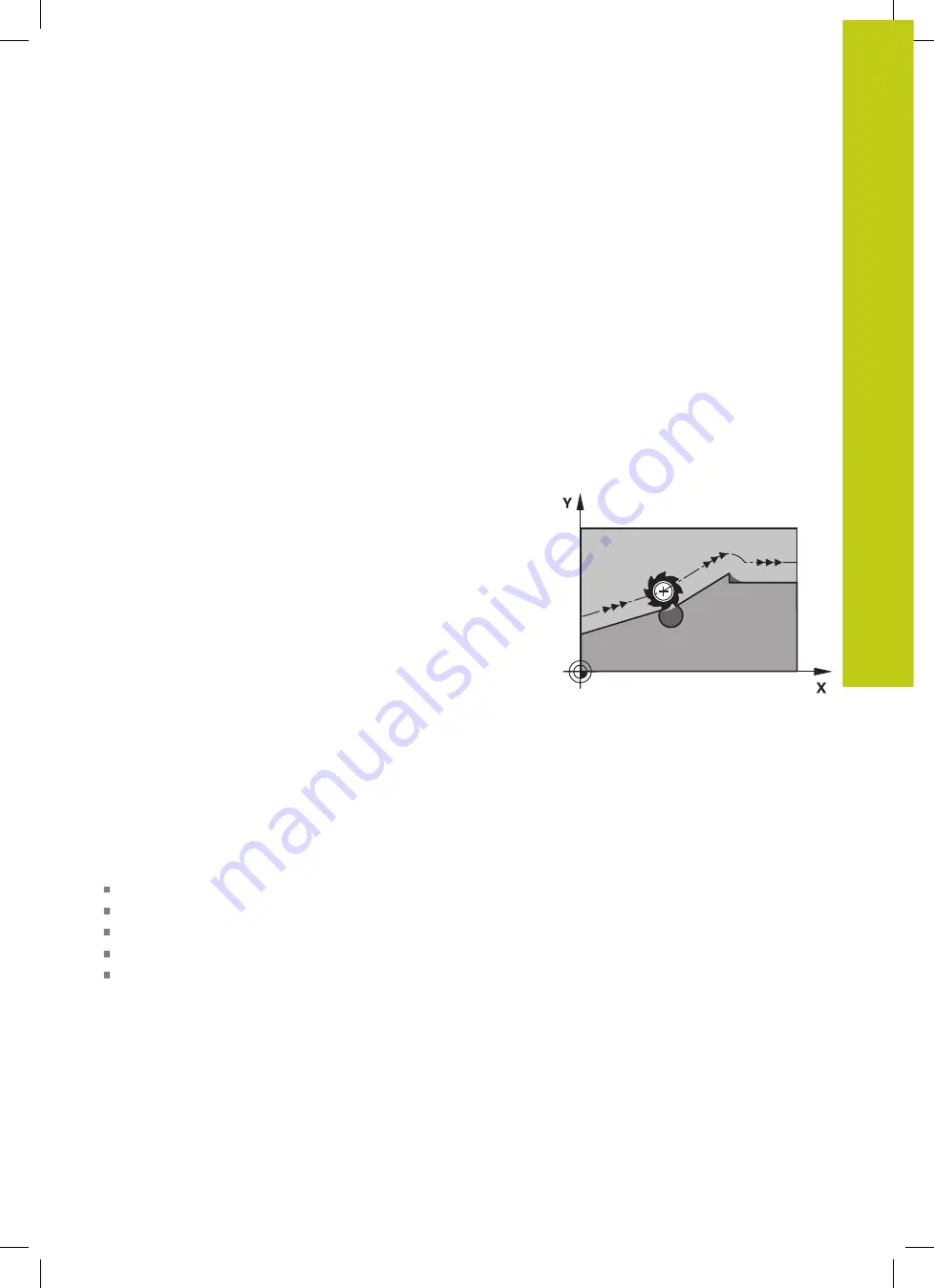

The TNC checks radius-compensated contours for undercuts and

tool path intersections, and calculates the tool path in advance from

the current block. Areas of the contour that might be damaged by

the tool are not machined (dark areas in figure). You can also use

M120 to calculate the tool radius compensation for digitized data or

data created on an external programming system. This means that

deviations from the theoretical tool radius can be compensated.

Use LA (

L

ook

A

head) behind M120 to define the number of blocks

(maximum: 99) that you want the TNC to calculate in advance.

Note that the larger the number of blocks you choose, the higher

the block processing time will be.

Input

If you enter M120 in a positioning block, the TNC continues the

dialog for this block by asking you the number of blocks LA that are

to be calculated in advance.

Effect

M120 must be located in an NC block that also contains radius

compensation

G41

or

G42

. M120 is then effective from this block

until

radius compensation is canceled with

G40

M120 LA0 is programmed, or

M120 is programmed without LA, or

another program is called with

%

the working plane is tilted with Cycle

G80

or the PLANE

function

M120 becomes effective at the start of the block.

Содержание TNC 620 Programming Station

Страница 1: ...TNC 620 User s Manual ISO programming NC Software 817600 04 817601 04 817605 04 English en 9 2016 ...

Страница 4: ......

Страница 5: ...Fundamentals ...

Страница 28: ...Contents 28 HEIDENHAIN TNC 620 ISO Programming User s Manual 9 2016 ...

Страница 57: ...1 First Steps with the TNC 620 ...

Страница 77: ...2 Introduction ...

Страница 110: ......

Страница 111: ...3 Fundamentals file management ...

Страница 166: ......

Страница 167: ...4 Programming aids ...

Страница 194: ......

Страница 195: ...5 Tools ...

Страница 234: ......

Страница 235: ...6 Programming contours ...

Страница 284: ......

Страница 285: ...7 Data transfer from CAD files ...

Страница 304: ......

Страница 305: ...8 Subprograms and program section repeats ...

Страница 323: ...9 Programming Q parameters ...

Страница 384: ......

Страница 385: ...10 Miscellaneous functions ...

Страница 407: ...11 Special functions ...

Страница 433: ...12 Multiple axis machining ...

Страница 475: ...13 Pallet management ...

Страница 480: ......

Страница 481: ...14 Manual Operation and Setup ...

Страница 549: ...15 Positioning with Manual Data Input ...

Страница 554: ......

Страница 555: ...16 Test Run and Program Run ...

Страница 590: ......

Страница 591: ...17 MOD Functions ...

Страница 622: ......

Страница 623: ...18 Tables and Overviews ...