S T E P 5

S T E P 5 – X / Z A s s e m b l y

28

docs.carbide3d.com

29

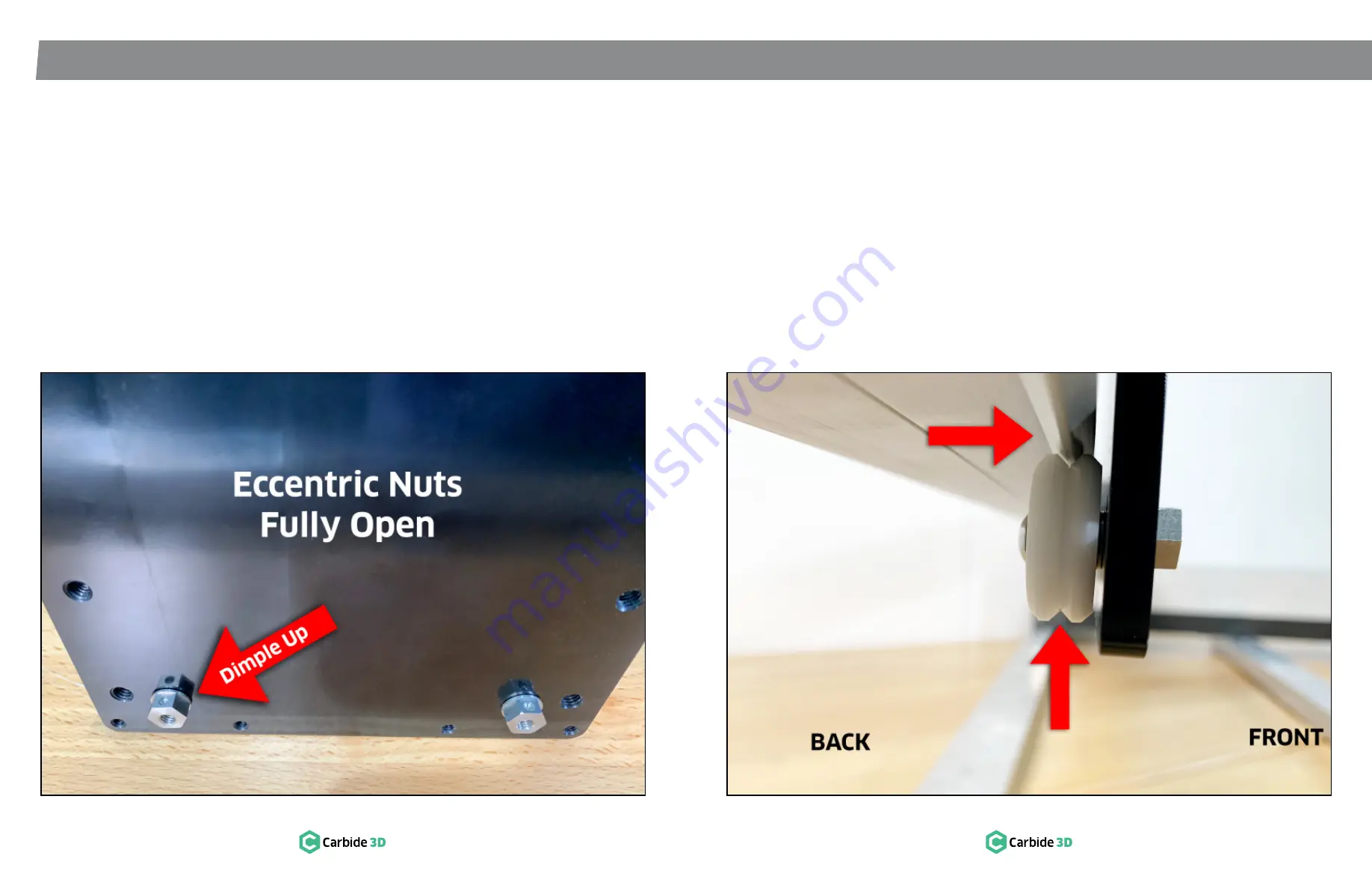

5.2 Open Eccentric Nuts

1. Locate the carrier plate assembly box and

the X-Axis drag chain support panel set aside

from the step 3 box.

2. Lay the X/Z carrier plate on the work surface

with the eccentrics face up and to the bottom.

3. Use the 10mm wrench to open the eccentrics.

See

Fig. 5-2

.

a. Dimple faces UP.

b. Refer back to

Figure 5-2

Figure 5-3

5.3 Pre‑Assemble V‑wheels

1. Pre-assemble the bottom two V-wheels for the

X/Z carrier plate in order (

see

Fig. 5-3

):

a. M5×22mm BHCS

b. V-wheel

c. M5 shim (washer)

NOTE:

Be sure the shim goes between the

V-wheel and the X/Z carrier plate.

5.4 Install X/Z Carrier Plate

1. Place the X/Z carrier plate onto the gantry,

aligning the two pre-installed V-wheels on the

top with the upper V-rail.

2. Use the 3mm hex key to install the bottom two

V-wheels on the back of the carrier plate.

See

Fig. 5-3

.

a. Be sure the V-wheels are properly seated

on the lower V-rail.

b. Use a 10mm wrench to hold eccentric nuts

in the fully open position (dimples up).

c. Use a 3mm hex key to tighten the BHCS to

secure the V-wheels to the eccentric nuts.

3. Check the carrier plate movement by rolling it

back and forth along the X-Axis gantry.

4. Use a 10mm wrench to tension the eccentric

nuts.

a. Rotate the eccentric nuts CLOCKWISE to

tension. Adjust a little at a time. Not much

tension is needed.

b. Reach under and spin the V-wheel with

your finger. If it rotates freely, keep

tightening until you feel some friction

against the rail.

Содержание Shapeoko 4 XXL

Страница 1: ...Shapeoko 4 XXL ASSEMBLY GUIDE...