87

86

Error message / error

Possible cause

Troubleshooting

Personnel

The cutting blade is oxide-

coated

The cutting blade is

overheating, too little

cooling water

Check the cooling water

Operating personnel

Lateral friction in the cut

Lower the feed rate, pull the

material slowly

Cracks on steel core;

eccentrical wear of the

cutting blade

The cutting blade is too

hard

Use a softer cutting blade

Operating personnel

Motor shaft bearing

Replace the motor shaft

bearing

STEPS AFTER TROUBLESHOOTING

After completion of the troubleshooting and before switching on, follow the following steps:

1. Check for tightness all threaded joints previously detached.

2. Check proper installation of all previously removed protective devices and covers.

3. Make sure that all tools, materials and other equipment have been removed from the working zone.

4. Clean the working zone and remove any spilled substances such as liquids, processing materials or similar.

5. Make sure that all safety devices of the machine function properly.

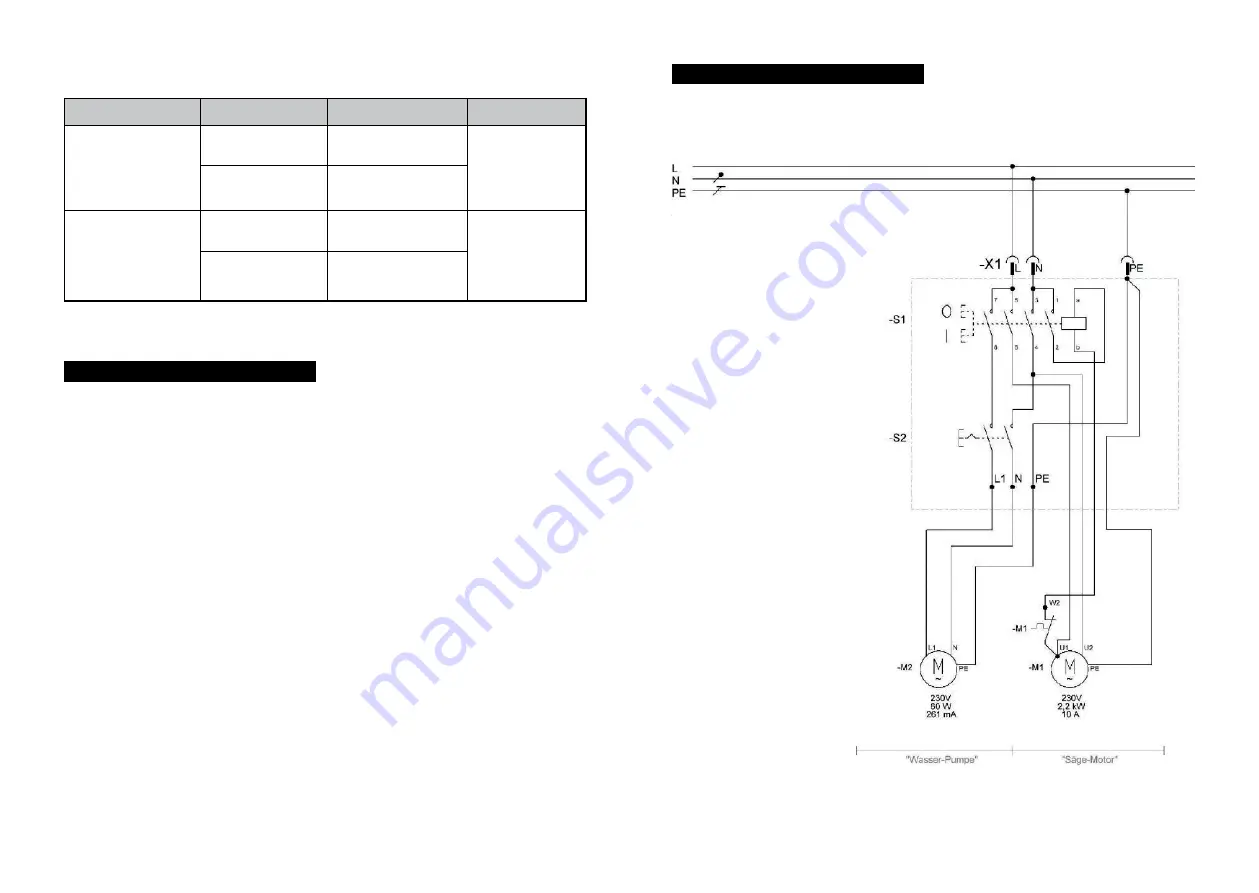

WIRING DIAGRAM - T-3510 - 230V

Содержание T-3510

Страница 45: ...89 88 WIRING DIAGRAM T 4010 230V WIRING DIAGRAM T 3510 400V...

Страница 46: ...91 90 WIRING DIAGRAM T 5010 230V WIRING DIAGRAM T 4010 400V...

Страница 47: ...93 92 WIRING DIAGRAM T 6010 230V WIRING DIAGRAM T 5010 400V...

Страница 48: ...95 94 WIRING DIAGRAM T 7010 230V WIRING DIAGRAM T 6010 400V...

Страница 50: ...99 98...

Страница 51: ...www carat tools eu www carat tools com www carat tools be www carat tools nl www carat tools dk...