24

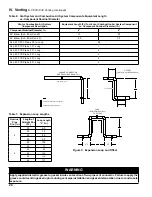

- The wall is 12” thick or less

- An air space of at least of that shown

in Figure 8 is maintained around

outside of the vent pipe to provide air

circulation

• If above three conditions cannot be

met simultaneously when penetrating

a combustible wall, use a single wall

thimble [Burnham Commercial part

numbers 102181-01 (4”) and 103419-01

(6”)].

• Thimble use is optional for non-

combustible wall.

• Insert thimble into cut opening from

outside. Secure thimble outside flange to

wall with nails or screws and seal ID and

OD with sealant material.

• When thimble is not used for non-

combustible wall, size and cut wall opening

such that a minimal clearance is obtained

and to allow easy insertion of vent pipe.

• Apply sealant between vent pipe and

thimble or wall opening to provide weather-

tight seal. Sealant should not restrain the

expansion of the vent pipe.

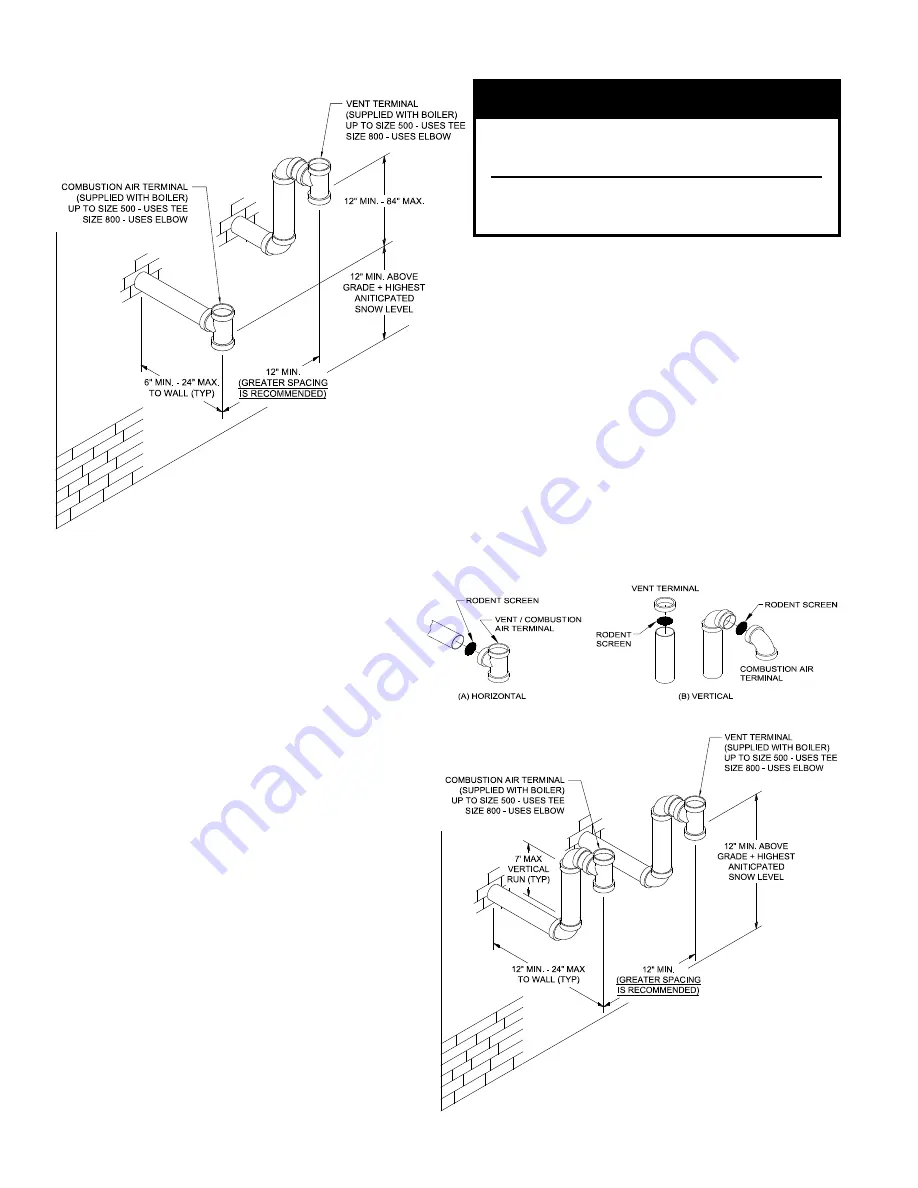

• Install Rodent Screen and Vent Terminal

(supplied with boiler). See Figure 10 for

appropriate configuration details.

Figure 10: rodent Screen installation

iV. Venting

B. CPVC/PVC Venting (continued)

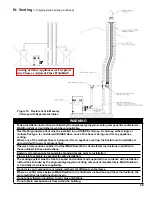

Figure 9B: Direct Vent - Sidewall Terminations (Optional)

Warning

all CPVC pipe supplied with boiler vent carton

must be used as part of vent system prior to

connecting supplied PVC vent terminal.

Methods of securing and sealing terminals to

the outside wall must not restrain the thermal

expansion of the vent pipe.

ii

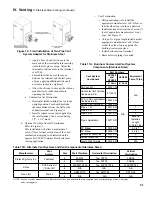

. Combustion Air Piping

• Do not exceed maximum combustion air

pipe length. Refer to Table 8.

• Size combustion air pipe wall penetration

opening to allow easy insertion of the pipe.

• Install Rodent Screen and Combustion Air

Terminal (supplied with boiler). See Figure

10 for appropriate configuration details.

• Apply sealant between combustion air pipe

and wall opening to provide weather-tight

seal.

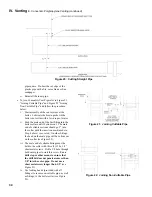

b. Optional Two-Pipe Snorkel Termination

See Figures 10 and 11.

This installation will allow a maximum of seven (7)

feet vertical exterior run of the vent/combustion air

piping to be installed on the CPVC/PVC horizontal

venting application.

Figure 11: Direct Vent - Optional Sidewall

Snorkel Terminations

Содержание Apex APX399

Страница 7: ...7 I Product Description Specifications and Dimensional Data continued Figure 1A Apex Model APX399 ...

Страница 8: ...8 Figure 1B Apex Model APX500 I Product Description Specifications and Dimensional Data continued ...

Страница 9: ...9 I Product Description Specifications and Dimensional Data continued Figure 1C Apex Model APX800 ...

Страница 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Страница 66: ...66 VIII Electrical continued ...

Страница 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

Страница 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

Страница 116: ...116 XIII Repair Parts continued ...

Страница 118: ...118 XIII Repair Parts continued ...

Страница 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Страница 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...

Страница 131: ...131 SERVICE RECORD DATE SERVICE PERFORMED ...