35

v.

Use the same method to join all remaining

vent components except for the terminal.

4.

Horizontal Vent Termination

a. Standard Concentric Termination

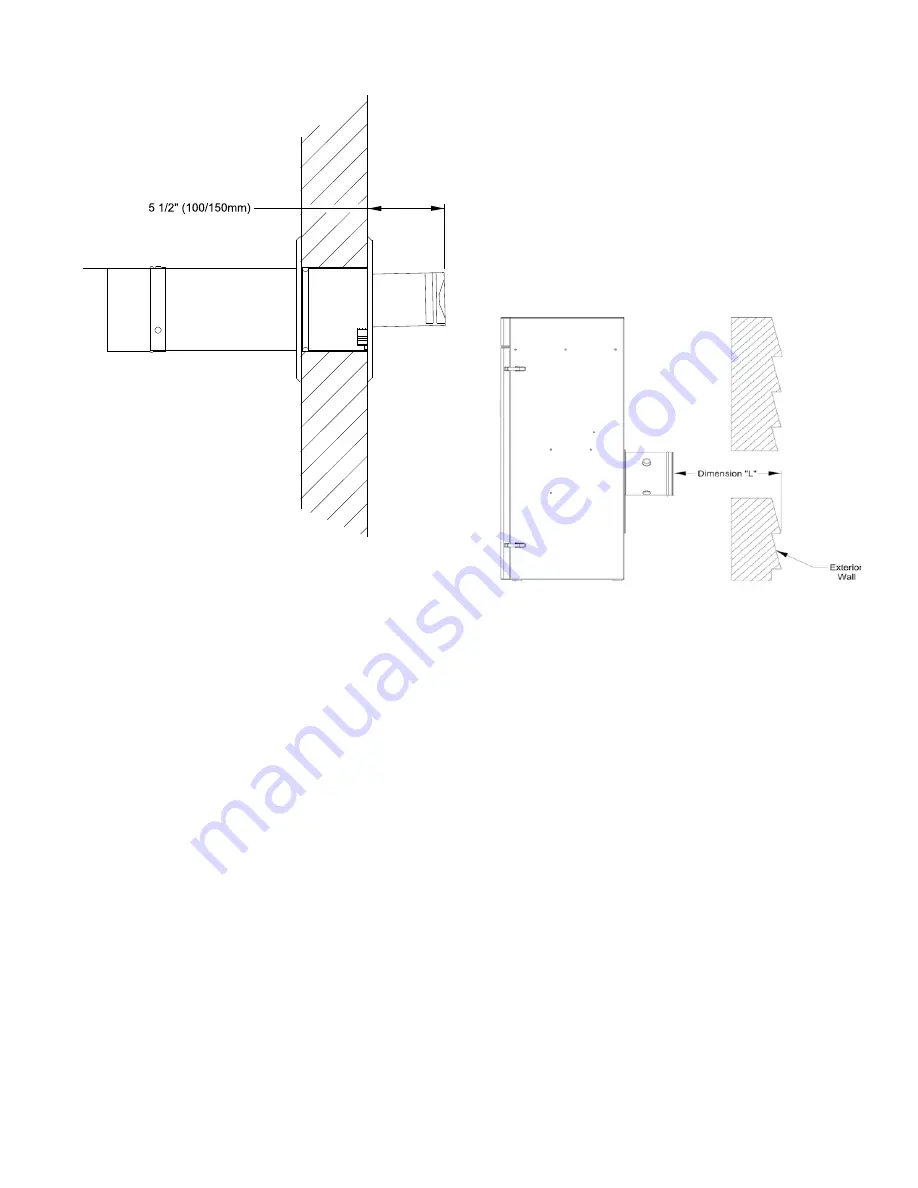

Refer to Figure 23.

i.

Permitted terminals for horizontal venting:

Horizontal (Wall) Terminal, [100/150 mm

(P/N 101809-01)] - see Table 13.

ii.

Concentric Vent components supplied with

the boiler are packed inside boiler carton

and include the following:

• Horizontal (Wall) Terminal,

• Horizontal (Wall) Terminal consists

of Straight section having plain male

end with locking band clamp installed;

Terminal Assembly with offset vent

termination, and Outside Wall Plate,

both riveted on the opposite end; overall

length is approximately 28-1/8”.

• Separate Inside Wall Plate

• Two Hardware Bags (each bag contains

four screws and four anchors) to attach

vent terminal Outside Wall Plate to

exterior wall and Inside Wall Plate to

interior wall.

iii.

For horizontal (sidewall) installation, the

Horizontal (Wall) Terminal will extend

past outer wall surface by 5½” (100/150

mm). See Figure 23 “Horizontal Concentric

Venting”.

iv.

Install the Horizontal (Wall) Terminal:

• Cut a 6½” (for 100/150 mm) at the

planned location of the horizontal

terminal.

• Measure dimension “L” from exterior

wall outer surface to the end of the last

fitting. See Figure 24 ‘Dimension “L”’.

Figure 23: Horizontal Concentric Venting

iV. Venting

E. Concentric Polypropylene Venting (continued)

Figure 24: Dimension “L”

• When factory Horizontal (Wall)

Terminal needs to be shortened, measure

dimension “L” plus 1¼” from inside

of the attached Outside Wall Plate and

mark the Horizontal (Wall) Terminal

outer pipe. To achieve a square cut of the

outer pipe, place several marks around

the outer pipe to establish a cut line. See

Figure 25 ‘ Cutting Vent Terminal Pipe’.

• Carefully cut the outer pipe at the marked

line using aviation shears, a hacksaw etc.

Ensure the pipe is cut square and cut end

is de-burred.

• Mark the end of the Horizontal (Wall)

Terminal inner polypropylene vent pipe

to extend 3/8” past the cut end of the

outer pipe. To achieve a square cut of the

inner pipe, place several marks around

the inner pipe to establish a cut line.

• Cut off the marked end of inner

polypropylene vent pipe with a fine tooth

blade hacksaw etc. and de-burr. See

Figure 25 “Cutting Vent Terminal Pipe.

This pipe can be removed from the

terminal to ease cutting, if desired.

Содержание Apex APX399

Страница 7: ...7 I Product Description Specifications and Dimensional Data continued Figure 1A Apex Model APX399 ...

Страница 8: ...8 Figure 1B Apex Model APX500 I Product Description Specifications and Dimensional Data continued ...

Страница 9: ...9 I Product Description Specifications and Dimensional Data continued Figure 1C Apex Model APX800 ...

Страница 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Страница 66: ...66 VIII Electrical continued ...

Страница 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

Страница 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

Страница 116: ...116 XIII Repair Parts continued ...

Страница 118: ...118 XIII Repair Parts continued ...

Страница 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Страница 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...

Страница 131: ...131 SERVICE RECORD DATE SERVICE PERFORMED ...