48

Vi. Water Piping and Trim

C. Standard Installation Requirements (continued)

C

. Standard Installation Requirements.

Observe the following guidelines when making the

actual installation of the boiler piping:

1.

Safety Relief Valve (Required)

- The relief valve is

packaged loose with boiler and must be installed in

the location shown in Figure 35 “Factory Supplied

Piping and Trim Installation”. The relief valve

must be installed with spindle in vertical position.

Installation of the relief valve must comply with

ASME Boiler and Pressure Vessel Code, Section IV.

The standard factory shipped relief valve is rated

for 50 PSI maximum working pressure. Optional

80 PSI and 100 PSI maximum working pressure

rated relief valves are available. If the valve is to be

replaced, the replacement valve must have a relief

capacity equal or exceeding the boiler AHRI Gross

Output rating (model APX500). Pipe the relief valve

discharge to a location where hot water or steam will

not create hazard or property damage if the valve

opens. The end of the discharge pipe must terminate

in an unthreaded pipe. If the relief valve is not

piped to a drain, it must terminate at least 6” above

the floor. Do not run relief valve discharge piping

through an area prone to freezing. The termination

of discharge piping must be in an area where it will

not become plugged by debris.

Warning

Safety relief valve discharge piping must be

piped such that the potential of severe burns

is eliminated. DO nOT pipe in any area where

freezing could occur. DO nOT install any shut-off

valves, plugs or caps. Consult Local Codes for

proper discharge piping arrangement.

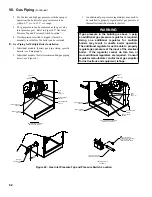

2.

Circulator (Required)

– Usually at least two

circulators will be required to properly install a

Apex™ Series boiler. See Paragraph B above for

information on sizing the circulators.

3.

Expansion Tank (Required)

– If this boiler is

replacing an existing boiler with no other changes

in the system, the old expansion tank can generally

be reused. If the expansion tank must be replaced,

consult the expansion tank manufacturer’s literature

for proper sizing.

4.

Fill Valve (Required)

– Either manual

(recommended) or automatic fill valve may be used.

However, if automatic refill is employed, a water

meter must be added to evaluate the makeup water

volume taken after initial fill and eliminate any

water leakage as early as possible.

5.

Automatic Air Vent (Required)

–At least one

automatic air vent is required. Manual vents will

usually be required in other parts of the system to

remove air during initial fill.

6.

Manual Reset High Limit (Required by some

Codes)

- This control is required by ASME CSD-1

and some other codes. Install the high limit in the

boiler supply piping just above the boiler with no

intervening valves. Set the manual reset high limit

to 200°F. Wire the limit per Figures 44 and 45A, in

Section VIII “Electrical”.

7.

Y-strainer (Recommended)

– A Y-strainer or

equivalent strainer removes heating system debris

from hydronic systems and protects boiler heat

exchanger from fouling up. Install the strainer

downstream of full port isolation valve, at the inlet

side of the circulator, for easy service.

8.

Flow Control Valve (Strongly Recommended)

–

The flow control valve prevents flow through the

system unless the circulator is operating. Flow

control valves are used to prevent gravity circulation

or “ghost flows” in circulator zone systems through

zones that are not calling for heat.

9.

Isolation Valves (Strongly recommended)

–

Isolation valves are useful when the boiler must be

drained, as they will eliminate having to drain and

refill the entire system.

10.

Drain Valve (Required)

– Drain valve is packaged

loose with boiler and must be installed in the

location shown in Figure 35 “Factory Supplied

Piping and Trim Installation”.

11.

Low Water Cutoff (Required by some Codes) –

LWCO with harness and LWCO transformer are

available as optional components. Order Complete

Kit (Part No. 102097-01) when required.

Содержание Apex APX399

Страница 7: ...7 I Product Description Specifications and Dimensional Data continued Figure 1A Apex Model APX399 ...

Страница 8: ...8 Figure 1B Apex Model APX500 I Product Description Specifications and Dimensional Data continued ...

Страница 9: ...9 I Product Description Specifications and Dimensional Data continued Figure 1C Apex Model APX800 ...

Страница 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Страница 66: ...66 VIII Electrical continued ...

Страница 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

Страница 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

Страница 116: ...116 XIII Repair Parts continued ...

Страница 118: ...118 XIII Repair Parts continued ...

Страница 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Страница 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...

Страница 131: ...131 SERVICE RECORD DATE SERVICE PERFORMED ...