18

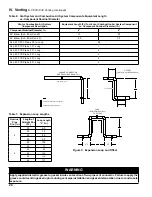

q. The minimum horizontal distance between any

adjacent individual module (boiler) roof vent

terminations is one (1) foot.

7. Use noncombustible ¾" pipe strap to support

horizontal runs and maintain vent location and

slope while preventing sags in pipe. Do not restrict

thermal expansion or movement of vent system.

Maximum support spacing four (4) feet. Avoid low

spots where condensate may pool. Do not penetrate

any part of the vent system with fasteners.

8. Maintain minimum clearance to combustible

materials. See Figure 2 for details.

9. Enclose vent passing through occupied or

unoccupied spaces above boiler with the material

having a fire resistance rating of at least equal to the

rating of adjoining floor or ceiling.

Note: For one or two family dwellings, fire

resistance rating requirement may not need to be

met, but is recommended.

10. Multiple individual module vertical vent pipes may

be piped through a common conduit or chase so that

one roof penetration may be made.

iV. Venting

A. General Guidelines (continued)

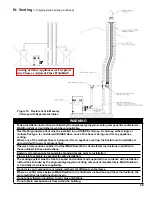

B.

CPVC/PVC Venting

Warning

all CPVC vent components (supplied with boiler)

must be used for near-boiler vent piping before

transitioning to Schedule 40 PVC pipe (aSTM

2665) components for remainder of vent system.

Warning

CPVC vent components must be used within

any interior space where air cannot circulate

freely, such as air inside a stud wall, and in

any boiler closet or chase way.

When using the CPVC/PVC vent options, the

use of CPVC is required when venting in vertical

or horizontal chase ways.

all condensate that forms in the vent must

be able to drain back to the boiler.

1.

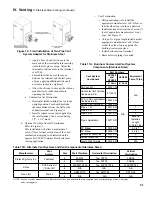

Components and Length Restrictions

a. See Table 5A for CPVC/PVC Vent & Air Intake

Components included with boiler, Table 5B for

CPVC/PVC Vent and Air Intake Components

(Installer Provided) required for Optional

Table 5a: CPVC/PVC Vent & air intake Components included With Boiler

Vent & air intake Components

Part

number

Quantity

aPX399 and aPX500

Standard Termination

Vent Kit

(P/n 102189-03)

includes

aPX800

Standard Termination

Vent Kit

(P/n 103253-01)

includes

4” Schedule 40 PVC Tee (Vent or Air Intake Terminals)

102190-02

2

N/A

6” Schedule 40 PVC 90° Elbow (Vent or Air Intake

Terminal)

103313-01

N/A

2

4” Stainless Steel Rodent Screen

102191-02

2

N/A

6” Stainless Steel Rodent Screen

102191-03

N/A

2

4” x 30” Schedule 40 CPVC Pipe

102193-02

1

N/A

6” x 30” Schedule 40 CPVC Pipe

103267-01

N/A

1

4” Schedule 80 CPVC 90° Elbow

102192-02

1

N/A

6” Schedule 80 CPVC 90° Elbow

103268-01

N/A

1

4 oz. Bottle of Transition Cement

102195-01

1

4 oz. Bottle of Primer

102194-01

1

4" Vent/4" Combustion Air CPVC/PVC Connector

102183-03

1

N/A

6" Vent/6" Combustion Air CPVC/PVC Connector

103270-01

N/A

1

4" Vent/4" Combustion Air CPVC/PVC Connector

Gasket

102185-02

1

N/A

6" Vent/6" Combustion Air CPVC/PVC Connector

Gasket

103248-01

N/A

1

Содержание Apex APX399

Страница 7: ...7 I Product Description Specifications and Dimensional Data continued Figure 1A Apex Model APX399 ...

Страница 8: ...8 Figure 1B Apex Model APX500 I Product Description Specifications and Dimensional Data continued ...

Страница 9: ...9 I Product Description Specifications and Dimensional Data continued Figure 1C Apex Model APX800 ...

Страница 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Страница 66: ...66 VIII Electrical continued ...

Страница 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

Страница 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

Страница 116: ...116 XIII Repair Parts continued ...

Страница 118: ...118 XIII Repair Parts continued ...

Страница 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Страница 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...

Страница 131: ...131 SERVICE RECORD DATE SERVICE PERFORMED ...