L3447

Emax DC

20/108

L3728

Doc. No.

Model

Apparatus

Scale

Page No.

1SDH000635R0002

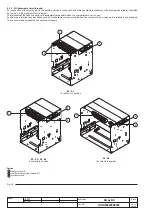

8.3.2

General inspection of the circuit-breaker

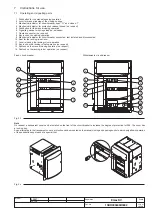

8.3.3 Checking contact wear

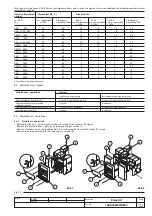

In order to ensure the gap A indicated in the table, you can adjust the

position of the shaft and of the operating mechanism.

1) Open the circuit-breaker

2) Remove the arcing chamber

3a) Adjust the distance of the moving contacts for E2-E3:

- loosen the screws in pos. 1 and the nuts in pos. 3 (FIG. 33a)

- proceed in the same way on the screws in pos. 2

- bring the bushes of the operating mechanism (pos. 5) to rest on

the shaft, tacking action on the nuts in pos. 4

- tighten the screws in pos.1 and the nuts in pos. 3 and 4

- close the circuit-breaker and check the gap A

3b) Adjust the distance of the moving contacts for E4-E6:

- loosen the screws in pos. 1 and 6, the nuts in pos. 3 and 8 (FIG.

33a and 33b)

- proceed in the same way on the screws in pos. 2

- bring the bushes of the operating mechanism (pos. 5) and the

bushes of the intermediate abutments (pos. 9) to rest on the shaft,

tacking action on the nuts in pos. 4 and the screws in position 7

- tighten the screws in pos. 1 and 6, and the nuts in pos. 3, 4 and

8

- close the circuit-breaker and check the gap A

4) If the gap A is not correct, open the circuit-breaker again and repeat

the procedure indicated in item 3a or 3b

5) If the gap A is correct, open the circuit-breaker again, seal with

yellow paint and reinstall the arcing chambers.

Circuit-breaker

E2 - E3

1

÷

1.9 mm

E4 - E6

0.8

÷

1.5 mm

Fig. 33

A

Item to be inspected

1 Operating mechanism/Electrical accessories

2 Arcing and main contacts

3 Arcing chambers

4 Main circuit - Busbars - Insulating contact

5 Earthing contacts (only for withdrawable circuit-

breaker)

6 Earth connection (only for fixed circuit-breaker)

7 Auxiliary circuit power supply voltage

8 Operating and control parts

Problem found

– Presence of dust on the internal parts

– Springs deformed or rusty

– Safety rings out of place, nuts or screws loose

– Wires and straps detached

– Traces of wear

– Incorrect adjustments: distance A - Fig. 33 is less than

1 mm for E2-E3 or less than 0.8 mm for E4-E6

– Presence of fumes or dust

– Presence of cracks in the external plastic structure

– Excessive difference in wear between the first and last

arc extinguishing plate

– Presence of dust or dirt on the insulating parts

– Safety rings out of place, screws or nuts loose

– Deformation or cracks of the insulating parts

– Insulating contacts oxidized (only for withdrawable

circuit-breaker)

– Wear or overheating marks or screws loose on the

connections to the terminals of the circuit-breaker

(only for fixed circuit-breaker)

Presence of rust or loose nuts

Presence of rust and/or loose nuts

Check the power supply voltage of the electrical

accessories of the operating mechanism

The operating tests, which must be carried out as shown

in paragraph 6.1 have shown defects in the components

Remedy

– Clean with brushes or dry cloths

– Replace damaged springs

– Put the rings back in place and tighten screws and

nuts appropriately

– Replace the straps and connect the detached wires

correctly

– Smooth the contacts with emery cloth

– Adjust according to the paragraph 8.3.3

–

Remove with compressed air and remove the fumes

and any slag with a brush

–

Replace the arcing chamber

– Replace the arcing chamber

– Clean with a brush or dry cloths

– Put the rings back in place and tighten screws and

nuts appropriately

– Ask ABB SACE to replace the damaged parts

– Remove the shutters and clean with a rough cloth

soaked in a suitable solvent and lubricate moderately

with neutral grease

– Tighten the screws suitably

Clean with a rough cloth soaked in a suitable solvent and

lubricate moderately with neutral grease. Tighten the

nuts completely

Clean with a rough cloth soaked in a suitable solvent,

fully tighten the earth connection and cover with neutral

grease

The releases and locking devices must operate normally

for values between 85% and 110% of the corresponding

rated voltage

Replace the defective parts or those with a faulty

operation (if necessary, ask ABB SACE)