Page - 36/95

AEMZP0BA - EPS-AC0 - User Manual

ESD happens when there is a rapid transfer from a charged part to another. This

rapid transfer has, in turn, two important effects:

1) It can determine, by induction, disturbs on the signal wiring and thus create

malfunctions. This effect is particularly critical in modern machines, with CAN

Bus communications, which are spread everywhere on the truck and which

carry critical information.

2) In the worst case and when the amount of charge is very high, the discharge

process can determine failures in the electronic devices; the type of failure can

vary from an intermittently malfunction to a completely failure of the electronic

device.

Three ways can be followed to prevent damages from ESD:

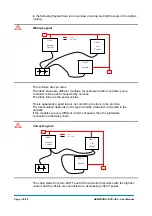

1) INSULATION: To prevent the controller from ESD, it is necessary to consider

that the operator is most of the time the source of ESD. When it gets in touch

with a device on the dashboard having metallic head terminal, the accumulated

charge will be directed from the head terminal to the wires of the device towards

the other units in the truck (e.g. the CAN Bus wires or the wires of the stepper

motor on the dashboard could be the transmission mean). As consequence a

huge inrush current will be generated getting the controller cut off or damaged.

U

To prevent ESD risk it is necessary to avoid that the devices connected to the

CAN communication system have exposed metallic head terminals. The

operator shall not get in touch with any metallic part of the devices CAN Bus

connected.

2) GROUNDING: when a complete isolation cannot be achieved, a good

grounding can divert the discharge current trough a “safe” path; the frame of a

truck can work like a “local earth ground”, absorbing excess charge.

U

It is strongly suggested to connect to the truck frame all the parts of the truck

that can get in touch with the operator (who is most of the time the source of

ESD). For example, we strongly suggest to connect the stepper motor frame

to the truck frame.

3) PREVENTION: Another important issue is the storing and handling of ESD-

sensitive electronic parts. Then, ensure the operator is grounded; test grounding

devices on a daily basis for correct functioning. This precaution is particularly

important during controller handling in the storing and installation phase.

Use anti-static containers when transferring ESD-sensitive material.

8.10 Fighting the dither

In Closed Loop application with potentiometers, the quantum nature of the Analog to

Digital conversion, generates dither on the steered wheel. This is a continuous

rolling of the steered wheel from a little bit right to a little bit left around the

commanded position. Obviously, both the potentiometers (SP POT and FB POT)

have noise and contribute to the problem.

There are some countermeasures to reduce or neutralize the dither.

Summary of Contents for EPS-AC0

Page 23: ...AEMZP0BA EPS AC0 User Manual Page 23 95 6 2 EPS AC0 Stepper Motor diagram Figure 6 2...

Page 24: ...Page 24 95 AEMZP0BA EPS AC0 User Manual 6 3 EPS AC0 Twin pot diagram Figure 6 3...

Page 55: ...AEMZP0BA EPS AC0 User Manual Page 55 95 12 3 2 RTC with Encoder and Feedback pot Figure 12 3...