Page - 32/95

AEMZP0BA - EPS-AC0 - User Manual

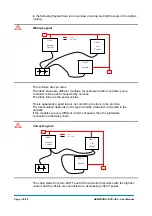

In the following figures there is an overview of wrong and right layouts of the cables

routing.

U

Wrong Layout:

The red lines are can wires.

The black boxes are different modules, for example traction controller, pump

controller and eps-ac0 connected by can bus.

The black lines are the power cables.

This is apparently a good layout, but can bring to errors in the can line.

The best solution depends on the type of nodes (modules) connected in the

network.

If the modules are very different in terms of power, then the preferable

connection is the daisy chain.

U

Correct Layout:

The chain starts from the –BATT post of the controller that works with the highest

current, and the others are connected in a decreasing order of power.

Node 1

Traction

Control

Node 2

Lift

Control

Node 3

eps-ac0

R

R

Can Bus

Power cables

Node 1

Traction

Control

Node 2

Lift

Control

Node 3

eps-ac0

R

R

Can Bus

Power cables

Summary of Contents for EPS-AC0

Page 23: ...AEMZP0BA EPS AC0 User Manual Page 23 95 6 2 EPS AC0 Stepper Motor diagram Figure 6 2...

Page 24: ...Page 24 95 AEMZP0BA EPS AC0 User Manual 6 3 EPS AC0 Twin pot diagram Figure 6 3...

Page 55: ...AEMZP0BA EPS AC0 User Manual Page 55 95 12 3 2 RTC with Encoder and Feedback pot Figure 12 3...