MNC-0300-011

7 of 26

Revision H

Unpacking and Installation

Vorsicht

Wenn Hohlleiterflansche nicht an das externe

Hohlleitersystem oder eine terminierte Ladung

angeschlossen sind, sollten sie mit einer Schutzkappe oder

Klebeband abgedeckt werden das beim Entfernen keine

Klebstoffreste hinterlässt. Xicom empfiehlt die Verwendung

von Kapton® Band, 3M Brand, #92, Xicom P/N 602-0001-

001. Band oder Kappe vor Endinstallation entfernen.

Nichtbeachtung könnte Kontamination des internen

Hohlleitersystems oder Beschädigung der Ausrüstung zur

Folge haben.

Use the following procedure to install the waveguides on your amplifier.

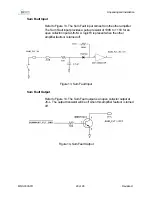

1. Position the interconnecting waveguide flange with the amplifier

waveguide flange. Make sure that the flanges can be mated without

strain or torsion.

2. If the two flanges cannot be properly aligned or if the installation is

subject to vibration, a flexible waveguide section should be utilized to

eliminate potential strain on the waveguide connection.

3. Insert any necessary gaskets and windows between the two flanges.

Note

If the connecting waveguide is to be pressurized at greater

than 5 PSI, a waveguide window must be installed at the

output flange of the amplifier. Use an absorptive type

gasket to preclude radiation leakage.

4. Start by hand tightening all waveguide mounting screws.

5. Tighten all mounting screws with the appropriate size Allen wrench.

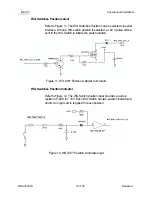

6. Use a sequential tightening procedure. Proceed as follows:

•

Partially tighten one of the screws (#1).

•

Move the tool to the screw that is diagonally opposite to the screw

tightened in step 1 (#2) and partially tighten that screw.

•

Move clockwise to the next screw to be tightened (#3) and partially

tighten that screw.

•

Move to the screw diagonally opposite screw #3 and partially

tighten that screw (#4).

•

If required, repeat this process for the remaining screws (#5-#6,

#7-#8).

•

When you reach the first screw tightened in this step (#1) increase

the torque on the screw and repeat the process until the screws

have all been tightened to the correct torque.

Summary of Contents for XTS-200C

Page 10: ...MNC 0000 010 2 Revision A6...

Page 38: ...MNC 0200 004 14 of 14 Revision C Safety Sicherheit...

Page 64: ...MNC 0300 011 26 of 26 Revision H Unpacking and Installation...

Page 72: ...Operation MNC 0400 012 8 of 8 Revision C...

Page 104: ...MNC 0500 010 32 Revision D Solid State Power Amplifier Communication and Protocol...

Page 122: ...MNC 0700 001 6 Revision F Service and Repair...

Page 131: ......

Page 132: ......

Page 133: ......

Page 134: ......

Page 135: ......

Page 136: ......

Page 137: ......

Page 138: ......

Page 139: ......

Page 140: ......

Page 144: ...MNC 0000 039 4 of 12 Revision 2 ODU SSPA Power Supply Removal...

Page 152: ...MNC 0000 039 12 of 12 Revision 2 ODU SSPA Power Supply Removal...

Page 155: ...MNC 0000 003 3 of 4 Revision B Operation Addendum SSPA M C Termination Cable...

Page 156: ...MNC 0000 003 4 of 4 Revision B Operation Addendum SSPA M C Termination Cable...

Page 160: ...MNC 0000 002 4 Revision A Protocol Adendum Block Upconverter...