52

Cutting frozen or

extremely hard product

Insufficient lubrication

Worn thrust bearings in

feed screw or agitator

Worn bearing in feed

adapter

Bent or loose clamps

Frozen product should be tempered to

approximately 27—35°F (-2.8—1.7°C). See

page 18.

Fill reduction units to correct level with rec-

ommended lubricant. See “Lubrication”,

page 38.

Replace thrust bearings. See pages 40–43.

Replace bearing. See pages 40–43.

Securely tighten feed adapter clamp screws

and/or replace clamps if necessary. See page

43.

Feed Screw

Breaks or

Cutting Head is

Damaged

Excessive Heat

or Noise from

Reduction

Units

Regular

Thumping

Sound

Loose Feed

Adapter

PROBLEM

CAUSE

CORRECTION

MAINTENANCE

Troubleshooting

Summary of Contents for COMITROL 2100

Page 2: ......

Page 28: ...Addendum A 26 This page intentionally left blank...

Page 84: ...6 This page intentionally left blank...

Page 94: ...16 This page intentionally left blank...

Page 95: ...17 GENERAL INFORMATION...

Page 101: ...23 INSTALLATION...

Page 104: ...26 This page intentionally left blank...

Page 110: ...32 This page intentionally left blank...

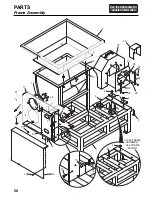

Page 131: ...53 PARTS...

Page 132: ...54 This page intentionally left blank...

Page 134: ...56 PARTS Tools See the Addendum for updated information...

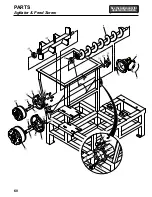

Page 138: ...60 PARTS Agitator Feed Screw See the Addendum for updated information...

Page 146: ...PARTS Motor and Drive Parts 68 See the Addendum for updated information...

Page 148: ...PARTS Electrical Assembly NEMA 70 See the Addendum for updated information...

Page 152: ...PARTS Electrical Assembly CE compliant 74 See the Addendum for updated information...

Page 156: ...78 PARTS Electrical Assembly Switches See the Addendum for updated information...

Page 165: ......