46

INSPECTION

WARNING:

In the event of an electri-

cal problem, only a qualified electrician

should inspect or repair the fault. Volt-

ages dangerous to life exist in the

starter enclosure! The power discon-

nect/lockout switch must be in the “O”

(OFF) position. Live voltages are still

present in the box even though discon-

nect is off. Always disconnect and lock

out power source before beginning

electrical inspection or repair.

The electrical assembly must be in good

working condition before operating this

machine. For a description of the amplifier

and safety switch operation and method for

checking this system, see pages 12–15.

Electrical schematics are located in the

starter enclosure and on pages 80–81.

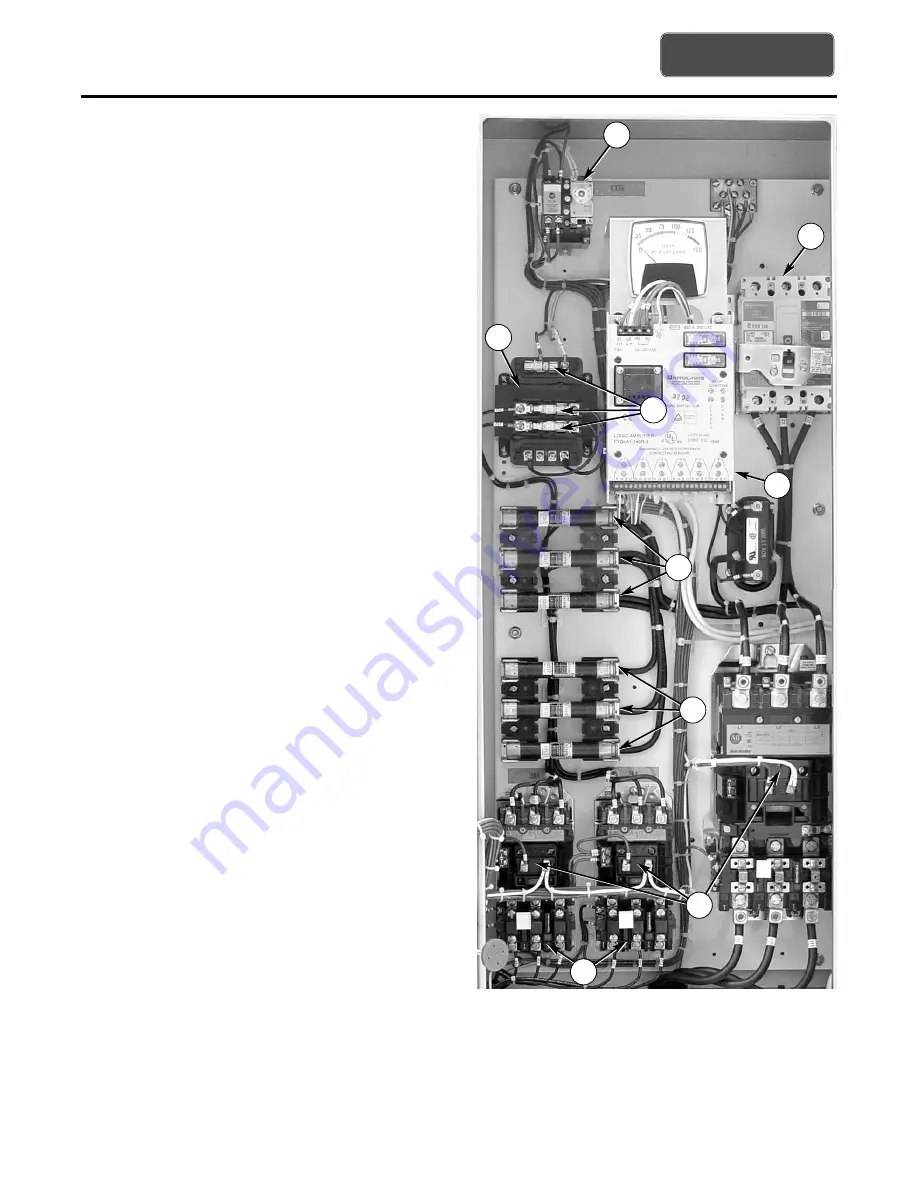

Refer to Figures 34 and 35 and inspect the

following:

Electrical enclosure:

Inspect interior of

electrical enclosure for corrosion. If a signifi-

cant amount of water accumulates in the

bottom of the starter enclosure, check the

breather drain. Breather drain should be

free from obstruction. Excess water could

also indicate an opening or loose fitting that

allows water to enter the enclosure. Check

all access points to the enclosure. Check

the gasket around door and window. Inspect

the push button assemblies and pilot light

assemblies for damage or corrosion.

Replace rubber boots and pilot light lenses if

damaged.

NOTE:

Electrical components that fail

due to water or chemical contamination

are not covered under the warranty.

MAINTENANCE

Electrical Assembly

Figure 34 — Typical starter enclosure interior

(NEMA). (1) Circuit Breaker, (2) Starter Coil,

(3) Heaters, (4) Amplifier, (5) Transformer,

(6) Transformer Fuses, (7) Fuses, Feed Screw

Motor, (8) Fuses, Agitator Motor, (9) Relay

*National Electrical Manufacturers Association

5

7

8

3

2

9

6

1

4

Summary of Contents for COMITROL 2100

Page 2: ......

Page 28: ...Addendum A 26 This page intentionally left blank...

Page 84: ...6 This page intentionally left blank...

Page 94: ...16 This page intentionally left blank...

Page 95: ...17 GENERAL INFORMATION...

Page 101: ...23 INSTALLATION...

Page 104: ...26 This page intentionally left blank...

Page 110: ...32 This page intentionally left blank...

Page 131: ...53 PARTS...

Page 132: ...54 This page intentionally left blank...

Page 134: ...56 PARTS Tools See the Addendum for updated information...

Page 138: ...60 PARTS Agitator Feed Screw See the Addendum for updated information...

Page 146: ...PARTS Motor and Drive Parts 68 See the Addendum for updated information...

Page 148: ...PARTS Electrical Assembly NEMA 70 See the Addendum for updated information...

Page 152: ...PARTS Electrical Assembly CE compliant 74 See the Addendum for updated information...

Page 156: ...78 PARTS Electrical Assembly Switches See the Addendum for updated information...

Page 165: ......