RESHARPENING CUTTING HEADS

URSCHALLOY cutting heads

may be

returned to the factory for resharpening, pro-

vided a certain amount of increased cutting

clearance is acceptable. With each grinding,

inside diameter is enlarged approximately

.010". Heads can be sharpened until amount

of oversize reaches unacceptable limit; gen-

erally .030" (.762 mm). When Urschalloy cut-

ting heads are no longer usable, they may be

returned to the factory for rebate. Cutting

heads being returned for sharpening or

rebate should be clean and free from foreign

material. See page 55 for ordering and

returning parts information.

FABRICATED cutting heads

with open-

ings between the horizontal separators of

0.150" to 1.500" may be resharpened by fil-

ing. Cutting heads with openings down to

0.100" (2.54 mm) should be returned to the

factory for resharpening; openings below

0.100" (2.54 mm) cannot be resharpened.

To resharpen fabricated cutting heads:

1.

Remove cutting head from machine.

See “Disassembly”, page 40.

2.

Use appropriate file.

See chart. Use a

smooth, second cut or bastard square file

or a smooth or second cut mill (flat) file.

3.

Place cutting head in a soft jaw vise

and file from outside to center.

File in

one direction at a 45° angle to the land of

the cutting surface (Figure 33).

NOTE:

Cutting head can be sharp-

ened until the land of the cutting edge is

filed to approximately 1/32" (.794 mm) in

width, then a new cutting head is

required.

4.

Remove burrs on inside of cutting

head

by honing each vertical land or

running an emery cloth counterclockwise

inside cutting head.

45

MAINTENANCE

Cutting Heads

Figure 33 — Sharpening fabricated cutting heads.

(1) File, (2) Land, (3) Run emery cloth counterclock-

wise inside the cutting head

1/32" MIN.

45°

2

1

Opening Between

Type of

Horizontal

File

Cutting Head

Separators

4" Square

A

0.150"

B

0.150"

J

0.180 & 0.240"

K

0.150 — 0.390"

6" Square

A

0.270 & 0.510"

J

0.300 — 0.510"

Special Column

0.300 & 0.390"

(14 & 10 column)

4" Flat

K

0.510"

Special Column

0.510"

(14 & 10 column)

6" Flat

J

0.750 — 1.500"

K

0.750 & 1.500"

Special Column

0.750 — 1.500"

(14, 10 & 7 column)

Summary of Contents for COMITROL 2100

Page 2: ......

Page 28: ...Addendum A 26 This page intentionally left blank...

Page 84: ...6 This page intentionally left blank...

Page 94: ...16 This page intentionally left blank...

Page 95: ...17 GENERAL INFORMATION...

Page 101: ...23 INSTALLATION...

Page 104: ...26 This page intentionally left blank...

Page 110: ...32 This page intentionally left blank...

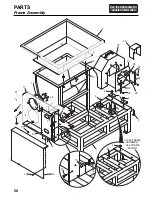

Page 131: ...53 PARTS...

Page 132: ...54 This page intentionally left blank...

Page 134: ...56 PARTS Tools See the Addendum for updated information...

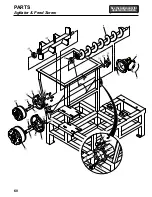

Page 138: ...60 PARTS Agitator Feed Screw See the Addendum for updated information...

Page 146: ...PARTS Motor and Drive Parts 68 See the Addendum for updated information...

Page 148: ...PARTS Electrical Assembly NEMA 70 See the Addendum for updated information...

Page 152: ...PARTS Electrical Assembly CE compliant 74 See the Addendum for updated information...

Page 156: ...78 PARTS Electrical Assembly Switches See the Addendum for updated information...

Page 165: ......