51

MAINTENANCE

Troubleshooting

PROBLEM

CAUSE

CORRECTION

Machine overload or

jam

Feed rate too high

Power source too low

Motor problem

Dull blades or cutting

edges in reduction head

Machine running back-

wards

Impeller tips worn

Dull blades or cutting

edges in reduction head

Incorrect impeller and

reduction head combi-

nation

Feed rate too high

causing impeller blades

to flex

Worn impeller motor

bearings

Burr on cutting head

mounting surface or

foreign material under

head

See “Machine Overload or Jam”, page 31.

See “Feeding Method”, page 30.

Maintain incoming power to at least 95% of

specified voltage.

Refer to motor manufacturer’s instruction

manual or contact Urschel Laboratories for

location of nearest authorized motor service

center.

See “Cutting Heads”, pages 44 & 45.

Rewire correctly. Impeller must turn clockwise

when viewed through product feed opening.

See “Electrical Power”, page 25.

Replace or send impeller to Urschel Laborato-

ries for repair. See “Inspection”, page 42.

See “Cutting Heads”, pages 44 & 45.

Contact an Urschel representative to set up a

test to determine the correct impeller and

reduction head combination.

Reduce feed rate by adjusting feed screw

speed. See “Feeding Method”, page 30.

Refer to motor manufacturer’s instruction

manual or contact Urschel Laboratories for

location of nearest authorized motor service

center.

Clean cutting head and support thoroughly.

Hone off any nicks or burrs from mounting

surfaces.

Motor

Frequently

Becomes

Overloaded

Poor Quality,

Ragged or

Oversized

Product

Impeller Tips

Contacting

Cutting Head

Summary of Contents for COMITROL 2100

Page 2: ......

Page 28: ...Addendum A 26 This page intentionally left blank...

Page 84: ...6 This page intentionally left blank...

Page 94: ...16 This page intentionally left blank...

Page 95: ...17 GENERAL INFORMATION...

Page 101: ...23 INSTALLATION...

Page 104: ...26 This page intentionally left blank...

Page 110: ...32 This page intentionally left blank...

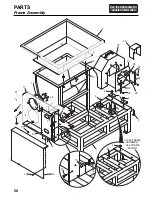

Page 131: ...53 PARTS...

Page 132: ...54 This page intentionally left blank...

Page 134: ...56 PARTS Tools See the Addendum for updated information...

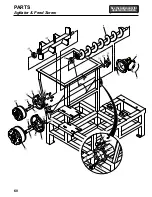

Page 138: ...60 PARTS Agitator Feed Screw See the Addendum for updated information...

Page 146: ...PARTS Motor and Drive Parts 68 See the Addendum for updated information...

Page 148: ...PARTS Electrical Assembly NEMA 70 See the Addendum for updated information...

Page 152: ...PARTS Electrical Assembly CE compliant 74 See the Addendum for updated information...

Page 156: ...78 PARTS Electrical Assembly Switches See the Addendum for updated information...

Page 165: ......