A.9

Addendum

Manual Page Number

Revision

Operation, Machine Overload or Jam

(continued)

:

The following applies

to the electrical system supplied from approximately October 2009 until

September 2018. See the previous page for motor overload information for

the current electrical system.

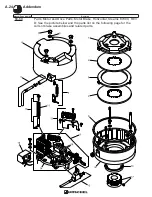

If the feed screw motor becomes overloaded causing the machine to

shut off, a display code of “oL1” will be displayed on the variable frequency

drive or

VFD (

1)

. Should this occur, turn the disconnect switch off and allow

at least 5 seconds for the fault

to clear. Contact maintenance

personnel to correct the cause of

the overload. Turn the disconnect

switch on. Press the “MASTER

RESET” button, then start in the

manner described in the manual.

Refer to the variable frequency

drive manufacturer’s manual for the

procedure when the digital operator

displays a different error code.

If the impeller or agitator motors

have overloaded, first press the

impeller reset (2)

and

agitator

reset (3)

buttons. Allow five

minutes for the thermal overloads to

cool. Next, press the master reset

button, then start in the manner

described in the manual.

Maintenance Cleaning: Add the following.

Cleaning a New Machine and Parts Before Use

Parts and equipment supplied by Urschel have not been sanitized.

Urschel recommends that the supplied parts and equipment be properly

cleaned and sanitized prior to use and in accordance with the requirements

of this application.

Maintenance, Lubrication: An optional hour meter is available to track

machine operating time. See the entry for the Electrical Enclosure Assembly

for more information.

1

2

3

Summary of Contents for COMITROL 2100

Page 2: ......

Page 28: ...Addendum A 26 This page intentionally left blank...

Page 84: ...6 This page intentionally left blank...

Page 94: ...16 This page intentionally left blank...

Page 95: ...17 GENERAL INFORMATION...

Page 101: ...23 INSTALLATION...

Page 104: ...26 This page intentionally left blank...

Page 110: ...32 This page intentionally left blank...

Page 131: ...53 PARTS...

Page 132: ...54 This page intentionally left blank...

Page 134: ...56 PARTS Tools See the Addendum for updated information...

Page 138: ...60 PARTS Agitator Feed Screw See the Addendum for updated information...

Page 146: ...PARTS Motor and Drive Parts 68 See the Addendum for updated information...

Page 148: ...PARTS Electrical Assembly NEMA 70 See the Addendum for updated information...

Page 152: ...PARTS Electrical Assembly CE compliant 74 See the Addendum for updated information...

Page 156: ...78 PARTS Electrical Assembly Switches See the Addendum for updated information...

Page 165: ......