INSPECTION

All parts should be cleaned, inspected for

serviceability, and repaired or replaced if

necessary.

Cutting Head:

Clean thoroughly with

water or cleaning solution and a stiff brush.

Use compressed air to remove any remain-

ing product. Inspect for damage or wear

(see “Cutting Heads”, pages 44 & 45).

NOTE:

Never use a wire brush or

sandpaper to clean cutting parts.

Seal and Seal Cover:

Inspect for wear

or damage and replace if necessary.

Feed Adapter and “O” Ring:

Remove

“O” ring and clean groove in feed adapter.

Inspect “O” ring and replace if necessary.

Feed Screw and Agitator:

Inspect

flights on feed screw and bearing surfaces

for nicks and burrs. File or hone if neces-

sary. Inspect pins in drive shaft ends of feed

screw and agitator for looseness or break-

age.

Bearings and Thrust Bearings:

Inspect for wear and cracks. Replace if nec-

essary.

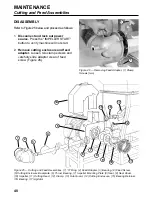

Impeller:

Clean and inspect for damage

or wear. When impeller inserts become worn

(rounded on leading edge), impeller should

be replaced or returned to the factory for re-

tipping (Figure 29). If impeller is worn exces-

sively and insert seats are damaged, it must

be replaced.

Seal in Cutting Head and Ring on

Impeller Mounting Hub:

Approximately

every six months the seal in the cutting

head support and its mating ring on the

impeller mounting hub should be

inspected for wear. With all cutting parts

removed, remove the fastener in the

center of the impeller mounting plate and

slide the mounting hub from the motor

shaft (see page 62). If necessary, remove

impeller mounting plate and use a gear

puller to remove hub. Inspect seal and

mating ring for cracking and wear.

Replace if necessary. Mating surfaces

must be clean and free of nicks and

scratches. Use an anti-seize compound on

motor shaft when reassembling to aid in

future removal of hub.

42

MAINTENANCE

Cutting and Feed Assemblies

Figure 29 — Repairable (left) and non-repairable

(right) Dio-cut impeller

Summary of Contents for COMITROL 2100

Page 2: ......

Page 28: ...Addendum A 26 This page intentionally left blank...

Page 84: ...6 This page intentionally left blank...

Page 94: ...16 This page intentionally left blank...

Page 95: ...17 GENERAL INFORMATION...

Page 101: ...23 INSTALLATION...

Page 104: ...26 This page intentionally left blank...

Page 110: ...32 This page intentionally left blank...

Page 131: ...53 PARTS...

Page 132: ...54 This page intentionally left blank...

Page 134: ...56 PARTS Tools See the Addendum for updated information...

Page 138: ...60 PARTS Agitator Feed Screw See the Addendum for updated information...

Page 146: ...PARTS Motor and Drive Parts 68 See the Addendum for updated information...

Page 148: ...PARTS Electrical Assembly NEMA 70 See the Addendum for updated information...

Page 152: ...PARTS Electrical Assembly CE compliant 74 See the Addendum for updated information...

Page 156: ...78 PARTS Electrical Assembly Switches See the Addendum for updated information...

Page 165: ......