79

TRAK Machine Tools

Southwestern Industries, Inc.

32240 - Printer and MMS - Installation & Printing Guide

17.

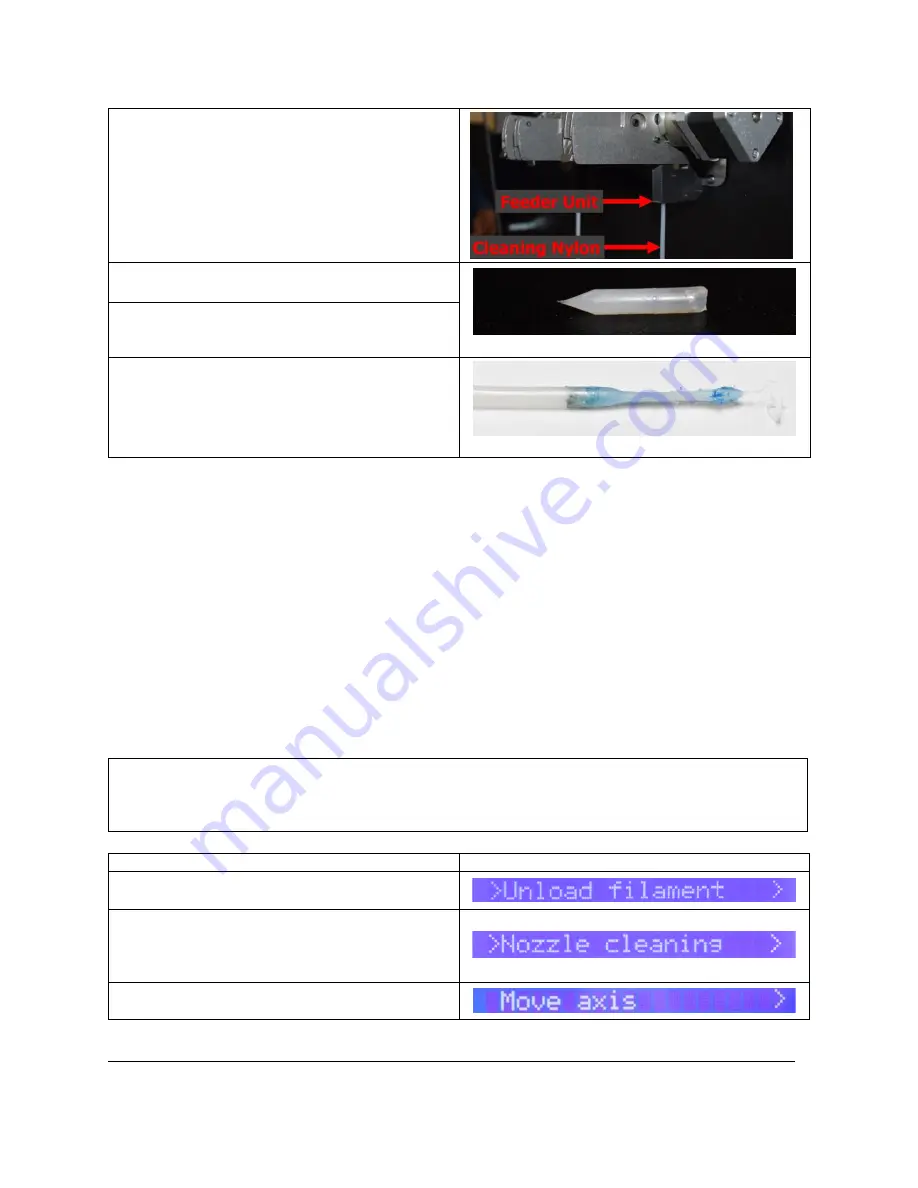

Feed the Cleaning Nylon into the Feeder

Unit.

18.

Inspect the Nylon tip to see if it is clean and

cone shaped.

Clean, Cone shaped Nylon tip

19.

If it looks like the picture on the right, your

nozzle is now ready to be loaded with new

filament!

20.

If it is not, repeat the Nozzle Cleaning

Operation until it looks clean and cone

shaped.

Dirty, misshaped Nylon Tip

5.3

Nozzle Changes

Once you verify that maintenance is up to date, have the correct file loaded, and learned to

load/unload/change filament and clean the nozzles, it's time to verify the nozzle setup! The nozzle is the

component of a 3D printer that actually extrudes the filament to build the part. There are many different

types and sizes available, and installing the correct one for the print is critical.

Nozzle Types

The nozzle type can have a large impact on the quality of your print, as well as how quickly you have to

replace the nozzles. Before you print, you should verify that you are using the correct nozzle type, based

on the material required for the print.

Nozzle Sizes

Nozzle sizes can have a huge impact on print quality, surface finish and print time. Before you print,

make sure the printers’ nozzles are configured based on the settings you selected on the slicer.

5.3.1

Nozzle Change Procedure

Step

Image

1.

Unload filament

from the nozzles being

changed.

2.

Perform the

Clean Nozzle Procedure

, this

will ensure most of the material within the

nozzle is removed, in order to make the

nozzle change much easier.

3.

Using the

Move Axis

function, move the Z

–

Axis about 200mm down.

CAUTION

When printing, you must install the correct nozzle diameter size and nozzle type based upon the print

requirements. Failure to install the correct nozzle size and type may result in bad prints, clogged

nozzles, rapid nozzle wear, and/or machine downtime.