e-STUDIO167/207/237

© February 2007 TOSHIBA TEC CORPORATION All rights reserved

FUSER / EXIT UNIT

13 - 6

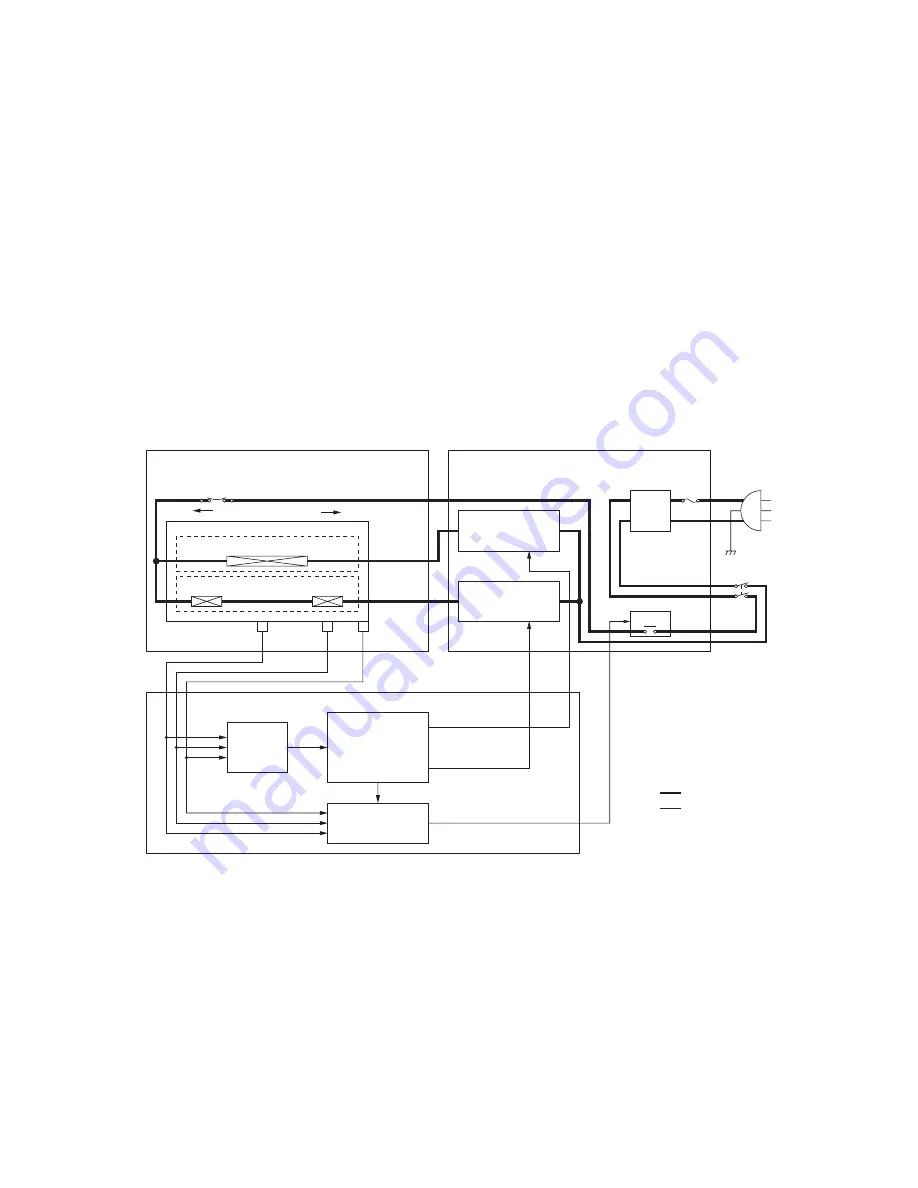

13.5 Fuser Unit Control Circuit

13.5.1

Configuration

In this equipment, the surface temperature of the fuser roller is controlled by turning ON/OFF 2 heater

lamps (center and side) which have different heat-generating positions with the command from the SoC

on the MAIN board. The surface temperature of the fuser roller is detected by 3 thermistors (center,

side and edge) and then the information of the temperature is transmitted to the SoC and each control

circuit. Based on the detected temperature, the SoC transmits the control signal of the heater lamp to

the control circuit (TRC: Triac) of each heater lamp on the switching regulator. The power supply to

each fuser roller is thus controlled by driving TRC. The SoC detects the overheating of the fuser roller.

In case that the surface temperature of the fuser roller has exceeded the specified temperature, the

SoC turns the heater lamp OFF.

If the SoC does not function for some reason and the fuser roller is abnormally overheated as the

result, a forcible power-OFF circuit transmits a relay-OFF signal to the switching regulator to shut off the

power supply to the heater lamp by opening the relay. In addition, if these control circuits do not func-

tion with thermistor abnormality or other reasons and the fuser roller is abnormally overheated as the

result, thermostat shut off the power supply to the heater lamps to protect the equipment.

Fig. 13-2

Main switch

Forcible power-off

circuit

A/D

converter

SoC

Side heater lamp

Center heater lamp

Fuser roller

Fuser thermostat

Edge

thermistor

Side

thermistor

Center

thermistor

Center heater lamp

control circuit

(TRC1)

Side heater lamp

control circuit

(TRC2)

Noise

filter

AC line

DC line

Fuser unit

Center heater lamp

control signal

Side heater lamp

control signal

Relay-OFF signal

MAIN board

L

N

Switching regulator

Front

Rear

Relay