Reelmaster 5500-D

Steering and Brakes

Page 7 - 12

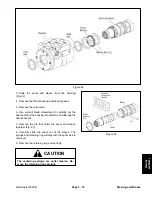

Rear Wheel Spindle Bushings

The rear wheel spindles must fit snugly in the rear axle.

Excessive movement of the spindle in the axle indicates

that the bushings are probably worn and must be re-

placed.

1. Disconnect the hydraulic hoses from the steering

cylinder. Put caps or plugs on the fittings and hoses to

prevent contamination.

Note:

To ease reassembly, tag each of the hoses to

show their correct position on the steering cylinder.

2. Remove the jamnut and thrust washer securing the

end of the axle pivot pin to the chassis (Fig. 14).

3. Jack up the frame (just ahead of the rear wheels) un-

til pressure is taken off the axle pivot pin. Support the

machine with jackstands to prevent it from falling.

4. Pull the axle pivot pin out. This will release the rear

axle and washer(s) from the frame. Carefully pull the en-

tire axle and wheel assembly out from under the ma-

chine.

Note:

Several washers may have been installed be-

tween the axle pivot tube and frame during manufac-

ture. Make sure the same number of washers are

installed during reassembly.

5. Remove one (1) jamnut to disconnect the tie rod end

from the spindle arm.

6. Remove the capscrew, spindle cap, retaining ring,

and washers that secure the wheel spindle into the axle

tube. Slide the spindle, washer, and wheel assembly out

of the axle tube to expose the bushings.

7. Use a punch and hammer to drive both bushings out

of the axle tube. Clean the inside of the axle tube to re-

move any dirt and foreign material.

8. Apply grease to the inside and outside of the new

bushings. Use an arbor press to install the bushings into

the top and bottom of the axle tube. The bushings must

be flush with the axle tube.

9. Wipe the spindle shaft with a rag to remove any dirt

and grease. Inspect the spindles for wear and replace

as necessary.

10.Install a washer onto the spindle shaft and push the

shaft through the axle tube. Hold the wheel and spindle

shaft assembly in place and install the thrust washer flat

washer and retaining ring onto the end of the spindle

shaft. Install the spindle cap and capscrew.

11. Connect the tie rod end to the spindle bracket with

two (2) jamnuts. Tighten the first nut to a torque of 25

to33 ft-lbs. (34 to 45 Nm). Install the second jamnut and

tighten against the other nut to secure tie rod end.

12.Mount the axle to the frame with the axle pin. Install

washer(s) and axle pivot pin. Secure the axle pivot pin

in place with the thrust washer and jamnut.

13.Remove the jackstands and lower the machine to the

floor.

14.Lubricate the steering spindles through the grease

fittings on the rear axle.

15.Install the hydraulic hoses to the steering cylinder.

16.Check steering cylinder hydraulic connections for

leaks.

Summary of Contents for 00075SL

Page 2: ...Reelmaster 5500 D ...

Page 4: ...Reelmaster 5500 D ...

Page 6: ...Reelmaster 5500 D ...

Page 64: ...Reelmaster 5500 D Hydraulic System Rev C Page 4 26 This page is intentionally blank ...

Page 170: ...Reelmaster 5500 D Page 5 40 Electrical System Rev C ...

Page 192: ...Reelmaster 5500 D Differential Axle Page 6 22 ...

Page 254: ...Reelmaster 5500 D Groomer Rev C Page 8 1 14 ...

Page 278: ...Reelmaster 5500 D Page 10 2 Electrical Diagrams Rev C ...

Page 284: ...Rev C Page 10 8 Harness Drawing Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Page 285: ...Rev C Page 10 9 Harness Diagram Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Page 286: ...Rev C Page 10 10 Harness Drawing Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Page 287: ...Rev C Page 10 11 Harness Diagram Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Page 288: ...Rev C Page 10 12 Harness Drawing Reelmaster 5500 D Serial Number Above 230000000 ...

Page 289: ...Rev C Page 10 13 Harness Diagram Reelmaster 5500 D Serial Number Above 230000000 ...

Page 290: ...Reelmaster 5500 D ...