Hydraulic

System

Reelmaster 5500-D

Hydraulic System (Rev. C)

Page 4 - 69

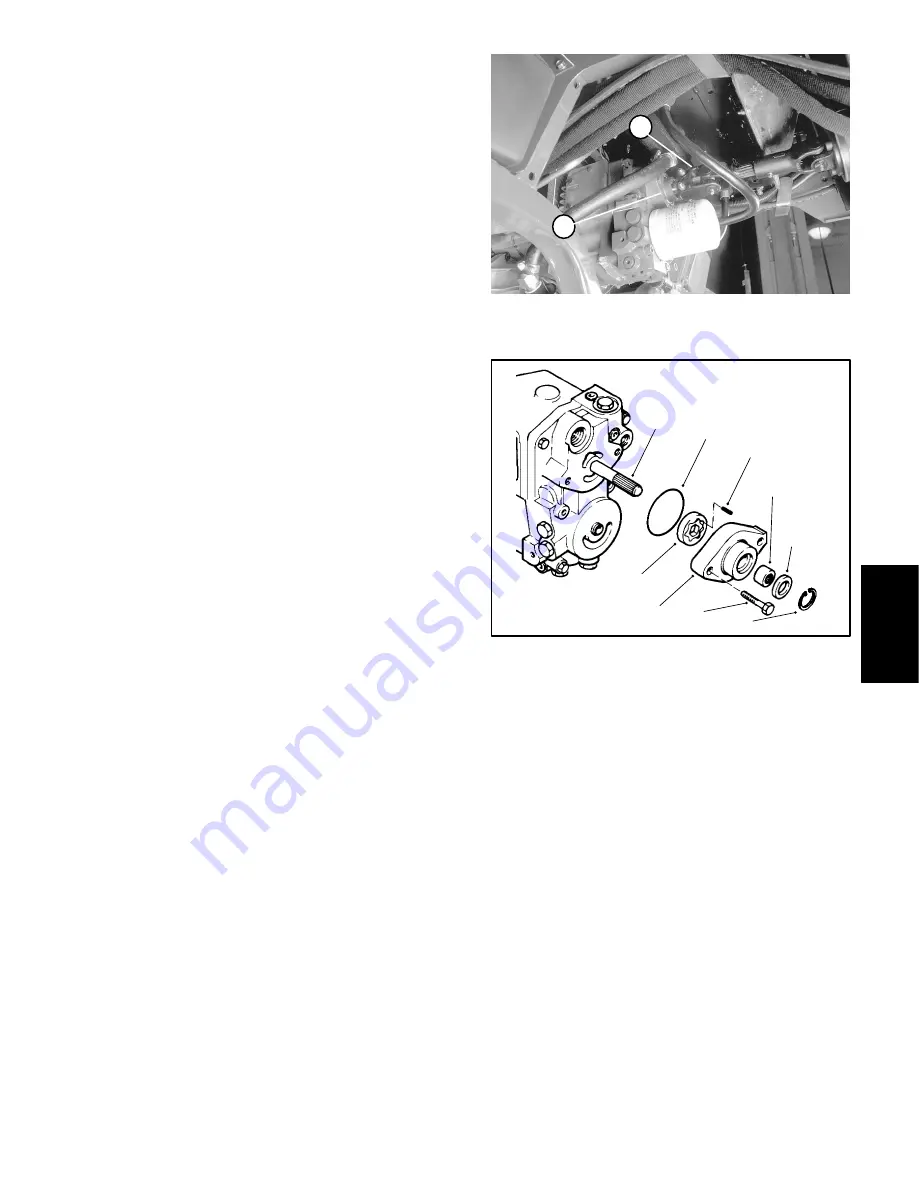

Charge Pump Replacement

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch.

2. Remove the transmission to engine driveshaft

(Fig. 82).

3. Remove the two (2) cap screws retaining the charge

pump cover. Remove the charge pump (Fig. 83).

4. Remove geroter drive pin from the groove in the

shaft.

5. Remove the geroter assembly from the charge pump

cover. Remove the shaft seal from the cover.

6. Each part should be inspected separately if they are

to be reused. If either of the geroter assembly parts

needs to be replaced, they should both be replaced. Al-

ways replace the O-ring.

7. Inspect the shaft bearing in the charge pump cover

for wear or damage. If replacement is necessary, re-

move the needle bearing from the cover using a suitable

puller. Press a new needle bearing into the cover using

a suitable press pin. When installed correctly, the bear-

ing cage will be flush to 0.020 inch (.51 mm) below the

surface of the seal counterbore in the front of the cover.

IMPORTANT: When installing the needle bearing,

the printed (numbered) end of the bearing cage

must face the press pin.

8. Install the geroter drive pin in the groove in the drive

shaft, and retain with petroleum jelly.

9. Before assembly, lubricate the geroter assembly

with clean hydraulic oil. Install the geroter assembly into

the charge pump cover. Install the O-ring and retain with

petroleum jelly.

IMPORTANT: Correct charge pump installation to

match engine rotation is determined by the position

of the charge pump cover on the transmission

housing. To prevent damage to transmission from

lack of replenishing oil from charge pump, the flat

on the charge pump cover must be on the right (to-

ward the heat exchanger ports).

10.With the flat on the charge pump cover to the right,

install the charge pump assembly over the drive shaft

and onto the transmission housing. Make sure the ger-

oter engages the drive pin in the shaft.

11. Tighten the charge pump cover cap screws to a

torque of 27 to 37 ft.-lb (37 to 50 N-m).

1. Drive

shaft

2. Charge

pump

Figure 82

2

1

8

7

6

4

3

5

9

2

1

1. Retaining

ring

2. Lip

seal

3. Cap

screw

4. Bearing

5. Housing

6. Gerotor

7. O-ring

8. Drive

shaft

9. Needle

bearing

Figure 83

12.Install a new shaft seal (see Shaft Seal Replace-

ment).

13.Before starting the engine, check the oil level in dif-

ferential housing and add the correct oil as necessary.

Start the engine and let it run for one to two minutes, then

turn the engine off and check the oil level again. Check

the transmission for leaks.

Summary of Contents for 00075SL

Page 2: ...Reelmaster 5500 D ...

Page 4: ...Reelmaster 5500 D ...

Page 6: ...Reelmaster 5500 D ...

Page 64: ...Reelmaster 5500 D Hydraulic System Rev C Page 4 26 This page is intentionally blank ...

Page 170: ...Reelmaster 5500 D Page 5 40 Electrical System Rev C ...

Page 192: ...Reelmaster 5500 D Differential Axle Page 6 22 ...

Page 254: ...Reelmaster 5500 D Groomer Rev C Page 8 1 14 ...

Page 278: ...Reelmaster 5500 D Page 10 2 Electrical Diagrams Rev C ...

Page 284: ...Rev C Page 10 8 Harness Drawing Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Page 285: ...Rev C Page 10 9 Harness Diagram Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Page 286: ...Rev C Page 10 10 Harness Drawing Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Page 287: ...Rev C Page 10 11 Harness Diagram Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Page 288: ...Rev C Page 10 12 Harness Drawing Reelmaster 5500 D Serial Number Above 230000000 ...

Page 289: ...Rev C Page 10 13 Harness Diagram Reelmaster 5500 D Serial Number Above 230000000 ...

Page 290: ...Reelmaster 5500 D ...