OPERATION

550E MM149 (9--00)

2-16

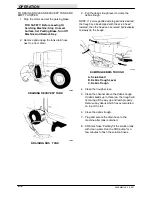

TOWING AND TRANSPORTING THE MACHINE

TOWING THE MACHINE

If the machine becomes disabled, it can be towed

from the front tie down holes or from the rear

bumper mounts.

A

B

FRONT TOWING LOCATION

A. Front Tie Down Holes

B. Towing Chain

This machine is not designed to be pushed. The

propelling system can be disengaged to prevent

damage to the propelling system when the

machine is being towed. Remove the cover plates

from the front drive wheels before towing the

machine. This will disengage the electric

propelling motors.

A

DISENGAGING PROPELLING MOTORS

A. Cover Plate

Only tow the machine for a short distance and do

not exceed 3.2 kp/h (2 mph). It is NOT intended

to be towed for a long distance or at a high speed.

ATTENTION! Do not tow machine for a

long distance or damage may occur to

the propelling system.

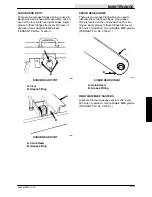

TRANSPORTING THE MACHINE

1. Position the machine at the loading edge of

the truck or trailer.

FOR SAFETY: Use truck or trailer that

will support the weight of the machine.

NOTE: Empty the recovery and solution tanks

before transporting the machine.

2. If the loading surface is not horizontal or is

higher than 380 mm (15 in) from the ground,

use a winch to load machine.

If the loading surface is horizontal AND is

380 mm (15 in) or less from the ground, the

machine may be driven onto the truck or

trailer.

LOADING SURFACE

A. Loading Surface Height

3. To winch the machine onto the truck or

trailer, attach the winching chains to the

machine.

A

B

ATTACHING WINCHING CHAINS

A. Front Tie Down Holes

B. Winching Chain

Summary of Contents for 550

Page 10: ...GENERAL INFORMATION 550E MM149 3 94 viii ...

Page 12: ...OPERATION 550E MM149 3 91 2 2 ...

Page 30: ...OPERATION 550E MM149 9 00 2 20 ...

Page 32: ...MAINTENANCE 550E MM149 3 91 3 2 ...

Page 62: ...MAINTENANCE 550E MM149 2 05 3 32 ...

Page 66: ...APPENDIX 550E MM149 3 91 4 4 ...

Page 74: ...STANDARD PARTS 550E MM149 5 01 6 4 Fig 2 Replacement Brushes 1 ...

Page 96: ...STANDARD PARTS 550E MM149 5 01 6 26 Fig 17 Electric Motor Group 1 2 3 4 5 6 ...

Page 105: ...STANDARD PARTS 6 35 550E MM149 5 01 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 106: ...STANDARD PARTS 550E MM149 5 01 6 36 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 117: ...STANDARD PARTS 6 47 550E MM149 5 01 Fig 31 Hydraulic Schematic 001330 005607 02361 550E ...

Page 118: ...STANDARD PARTS 550E MM149 5 01 6 48 Fig 32 Hydraulic Schematic 005608 11118 550E ...

Page 168: ...OPTIONS 550E MM149 9 99 8 18 ...

Page 182: ...BREAKDOWNS 550E MM149 10 10 9 14 ...