OPERATION

550E MM149 (9--00)

2-10

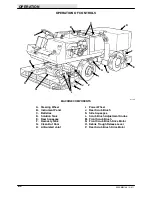

MACHINE OPERATION

NORMAL SCRUBBING OPERATION

A normal scrubbing operation consists of eight

typical operations: pre-start checklist, starting

machine, filling solution tank, scrubbing, draining

recovery tank and emptying hopper, post

operation checklist -- motor operating, stopping

machine, and post operation checklist -- motor

stopped.

PRE-START CHECKLIST

lists things to check

before starting the machine.

TO START MACHINE

lists the steps required to

start the machine.

TO FILL SOLUTION TANK

lists the steps

required to fill the solution tank.

TO SCRUB

lists things to keep in mind before and

during the scrubbing operation.

TO DRAIN AND CLEAN RECOVERY TANK AND

EMPTY HOPPER

lists the steps required to

empty the debris hopper and the recovery tank.

POST OPERATION CHECKLIST -- MOTOR

OPERATING

lists things to check before stopping

the machine motor.

TO STOP MACHINE

lists the steps required to

stop the machine.

POST OPERATION CHECKLIST -- MOTOR

STOPPED

lists things to check after stopping the

machine motor.

PRE-START CHECKLIST

Check under the machine for leak spots.

Check the brakes and controls for proper

operation.

Check the service records to determine service

requirements.

TO START MACHINE

NOTE: Before starting machine, perform the

pre-start checks.

1. The machine operator must be in the

operator’s seat with the directional pedal in

the “neutral” position and with a foot on the

brake pedal.

FOR SAFETY: Before Starting Machine,

Make Sure All Safety Devices Are In

Place And Operate Properly.

2. Release the parking brake..

3. Turn the master power key switch to the

“ON” position.

4. Press the start push button to start the

motor.

5. Drive the machine to the solution filling site.

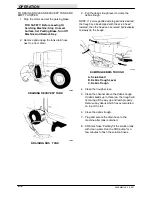

TO FILL SOLUTION TANK

1. Stop the motor and set the parking brake.

FOR SAFETY: Before Leaving Or

Servicing Machine; Stop On Level

Surface, Set Parking Brake, Turn Off

Machine And Remove Key.

2. Open the solution tank fill door or cap.

3. Pour the required amount of detergent into

the tank. Fill the tank with water to 1 in

(25 mm) below the tank opening. The water

must not be hotter than 130

_

F (54

_

C) or

tank damage may occur.

FOR SAFETY: When using machine,

follow mixing and handling instructions

on chemical containers.

Summary of Contents for 550

Page 10: ...GENERAL INFORMATION 550E MM149 3 94 viii ...

Page 12: ...OPERATION 550E MM149 3 91 2 2 ...

Page 30: ...OPERATION 550E MM149 9 00 2 20 ...

Page 32: ...MAINTENANCE 550E MM149 3 91 3 2 ...

Page 62: ...MAINTENANCE 550E MM149 2 05 3 32 ...

Page 66: ...APPENDIX 550E MM149 3 91 4 4 ...

Page 74: ...STANDARD PARTS 550E MM149 5 01 6 4 Fig 2 Replacement Brushes 1 ...

Page 96: ...STANDARD PARTS 550E MM149 5 01 6 26 Fig 17 Electric Motor Group 1 2 3 4 5 6 ...

Page 105: ...STANDARD PARTS 6 35 550E MM149 5 01 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 106: ...STANDARD PARTS 550E MM149 5 01 6 36 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 117: ...STANDARD PARTS 6 47 550E MM149 5 01 Fig 31 Hydraulic Schematic 001330 005607 02361 550E ...

Page 118: ...STANDARD PARTS 550E MM149 5 01 6 48 Fig 32 Hydraulic Schematic 005608 11118 550E ...

Page 168: ...OPTIONS 550E MM149 9 99 8 18 ...

Page 182: ...BREAKDOWNS 550E MM149 10 10 9 14 ...