OPERATION

2-9

550E MM149 (12--05)

SOLUTION CONTROL LEVER

The solution control lever controls the solution

flow. Pushing the lever into the “CLOSED”

position stops solution flow to the floor. Pulling the

lever into the “OPEN” position allows solution to

flow.

STEERING WHEEL

The steering wheel controls a steering cylinder

which is mounted between the two halves of the

machine.

Do not turn the steering wheel excessively when

the motor is not running. An articulated trunnion

connects the front and rear sections of the

machine so that the rear section always follows

the path of the front section.

A horn button is located in the center of the

steering wheel.

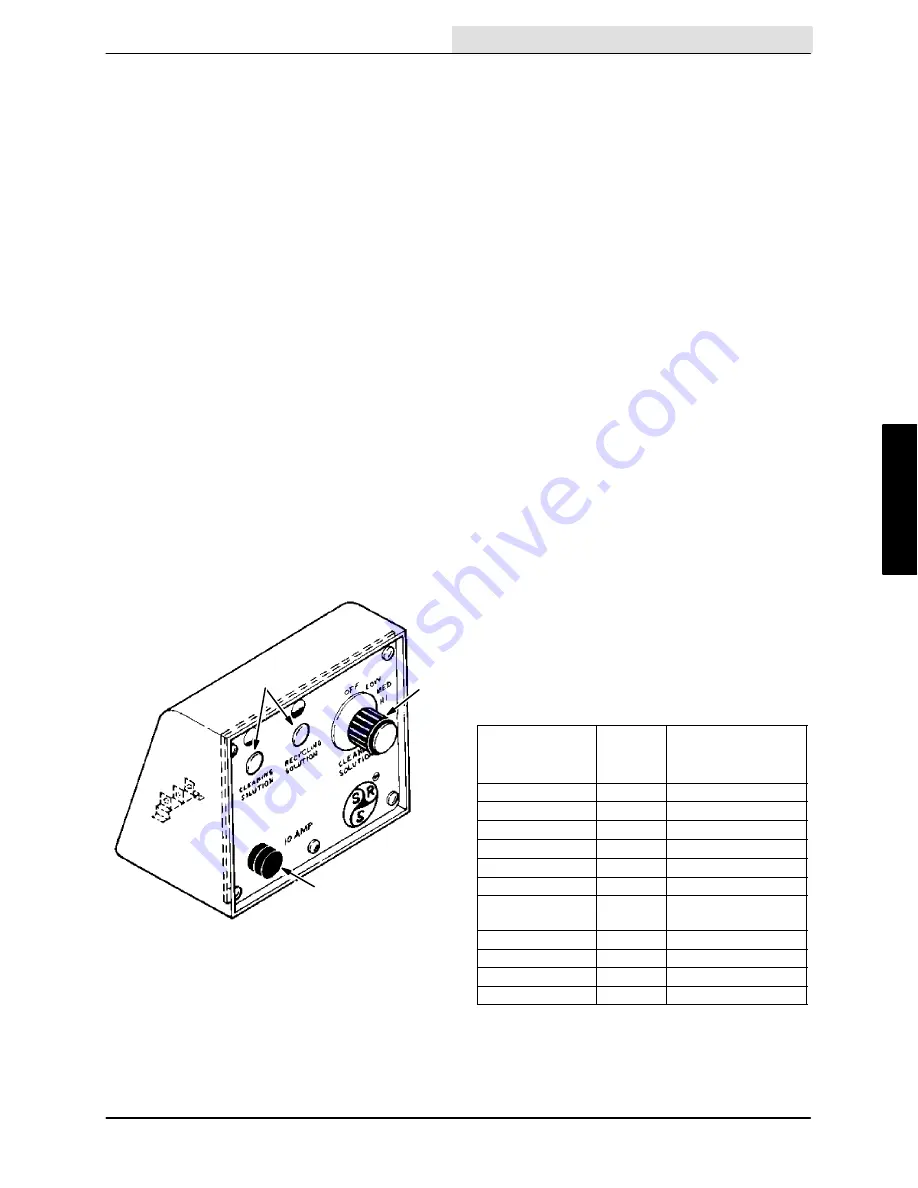

SRS LIQUID LOW LEVEL LAMPS (OPTION)

The SRS liquid low level lamps option includes

two indicating lamps. The cleaning solution lamp

lights when the cleaning solution is low. The

recycling solution lamp lights when the recycling

solution is low.

A

B

C

00351

SRS CONTROL PANEL

A. Liquid Low Level Indicator Lamps

B. Cleaning Solution Flow Control

Knob

C. SRS Pump System Fuse

SRS CLEANING SOLUTION FLOW CONTROL

KNOB (OPTION)

The SRS cleaning solution flow control knob

controls the cleaning solution pump which pumps

cleaning solution into the solution flow to the floor.

The “LOW,” “MED,” and “HI” levels indicate the

rate of cleaning solution flow. The “LOW” level

causes the pump to deliver one-fourth capacity,

“MED” level one-half capacity, and “HI” level full

pump capacity of cleaning solution into the

solution flow to the floor.

The “OFF” position shuts off the cleaning solution

flow.

FUSES AND CIRCUIT BREAKERS

Fuses are a one-time circuit protection device

designed to stop the flow of current in the event of

a circuit overload. Never substitute higher value

fuses than those specified in this manual. The

fuses are located in the control panel.

Circuit breakers are resetable circuit protection

devices designed to stop the flow of current in the

event of a circuit overload. Once tripped, circuit

breakers must be manually reset. The scrub

brush drive circuit is located in the instrument

panel.

If the overload which caused the circuit breaker to

trip is still present in the circuit, the circuit breaker

will continue to stop current flow until the overload

is corrected. The chart below shows the various

fuses and circuit breakers and the electrical

components they protect.

PROTECTIVE

DEVICE

PROTECTED

RATING CIRCUIT

Fuse

200 A

Complete machine

Fuse

15 A

Horn

Fuse

15 A

Operating lights

Fuse

15 A

Hazard light

Fuse

15 A

Auto--squeegee

Fuse

1 A

Level sensing

Fuse

50 A

MFR control, drive

Fuse

50 A

MFR control, drive

motors

Fuse

120 A

Motor

Fuse

5 A

SRS pumps

Circuit

30 A

Scrub brush drive

CB--6

15 A

Lights

Summary of Contents for 550

Page 10: ...GENERAL INFORMATION 550E MM149 3 94 viii ...

Page 12: ...OPERATION 550E MM149 3 91 2 2 ...

Page 30: ...OPERATION 550E MM149 9 00 2 20 ...

Page 32: ...MAINTENANCE 550E MM149 3 91 3 2 ...

Page 62: ...MAINTENANCE 550E MM149 2 05 3 32 ...

Page 66: ...APPENDIX 550E MM149 3 91 4 4 ...

Page 74: ...STANDARD PARTS 550E MM149 5 01 6 4 Fig 2 Replacement Brushes 1 ...

Page 96: ...STANDARD PARTS 550E MM149 5 01 6 26 Fig 17 Electric Motor Group 1 2 3 4 5 6 ...

Page 105: ...STANDARD PARTS 6 35 550E MM149 5 01 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 106: ...STANDARD PARTS 550E MM149 5 01 6 36 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 117: ...STANDARD PARTS 6 47 550E MM149 5 01 Fig 31 Hydraulic Schematic 001330 005607 02361 550E ...

Page 118: ...STANDARD PARTS 550E MM149 5 01 6 48 Fig 32 Hydraulic Schematic 005608 11118 550E ...

Page 168: ...OPTIONS 550E MM149 9 99 8 18 ...

Page 182: ...BREAKDOWNS 550E MM149 10 10 9 14 ...