OPERATION

2-7

550E MM149 (8--02)

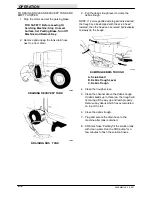

PIVOT LOCK PIN

A pivot lock pin is provided to lock the pivot joint

located between the front and rear machine

sections. The pin is hung on the front section of

the machine adjacent to the machine pivot. To

lock the sections, turn the machine so the pivot

lock holes line up, then insert the pin through the

holes. The pin will prevent the machine from

pivoting and creating a pinch area.

WARNING: Crush Hazard Between Front

And Rear Halves Of Machine. Put

Locking Pin In Pivot Lock Before Going

Between Machine Halves.

B

C

A

00251

PIVOT LOCK PIN IN USE

A. Machine Trailer Section

B. Machine Tractor Section

C. Pivot Lock Pin

OPERATOR SEAT

The operator seat is of a fixed back style with a

forward-backward adjustment. To adjust the seat,

loosen the seat mounting bolts, slide the seat to

the position desired, and tighten the bolts.

HAZARD LIGHT SWITCH (OPTION)

The hazard light switch is present on machines

with the hazard light option. Flip the switch toggle

up to turn the light on. Flip the switch toggle down

to turn the light off.

ROTATING LIGHT SWITCH (OPTION)

The rotating light switch is present on machines

with the rotating light switch option. Flip the switch

toggle up to turn the light on. Flip the switch

toggle down to turn light off.

OPERATING LIGHTS SWITCH (OPTION)

The operating lights switch is present on

machines with the operating lights option. It

controls the headlights, taillights, and the brush

spot light. Flip the switch toggle up to turn the

lights on. Flip the switch toggle down to turn the

lights off.

MASTER POWER SWITCH

The key-operated master power switch controls

the machine power. Turning the switch key

clockwise to the “on” position allows power to

flow. Turning the switch key counterclockwise to

the “off” position stops all power flow.

Always remove the key from the switch when the

machine is left unattended.

MOTOR START PUSH BUTTON

The motor start push button controls the motor

starting circuit of the main electric motor. Press

the push button switch momentarily to start the

motor.

NOTE: The operator must be on the seat when

starting the motor so that the safety switch,

located under seat, will be closed. The parking

brake must also be released in order to start the

machine.

CLIMB PUSH BUTTON

The red climb push button, when pressed,

energizes a special circuit which allows extra

voltage to be applied to the drive motors, giving

the machine more power to climb ramps. Press

the push button switch to engage the climb circuit.

To disengage the climb circuit, press the level

push button. Pressing the directional pedal into

the “reverse” position will also disengage the

climb circuit.

LEVEL PUSH BUTTON

The level push button, when pressed, stops the

climb circuit operation. The push button is used

when the machine is still moving and when the

climb circuit is no longer needed. The level or

normal speed range is recommended for optimum

scrubbing performance.

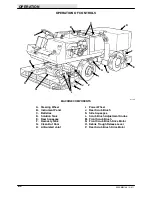

Summary of Contents for 550

Page 10: ...GENERAL INFORMATION 550E MM149 3 94 viii ...

Page 12: ...OPERATION 550E MM149 3 91 2 2 ...

Page 30: ...OPERATION 550E MM149 9 00 2 20 ...

Page 32: ...MAINTENANCE 550E MM149 3 91 3 2 ...

Page 62: ...MAINTENANCE 550E MM149 2 05 3 32 ...

Page 66: ...APPENDIX 550E MM149 3 91 4 4 ...

Page 74: ...STANDARD PARTS 550E MM149 5 01 6 4 Fig 2 Replacement Brushes 1 ...

Page 96: ...STANDARD PARTS 550E MM149 5 01 6 26 Fig 17 Electric Motor Group 1 2 3 4 5 6 ...

Page 105: ...STANDARD PARTS 6 35 550E MM149 5 01 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 106: ...STANDARD PARTS 550E MM149 5 01 6 36 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 117: ...STANDARD PARTS 6 47 550E MM149 5 01 Fig 31 Hydraulic Schematic 001330 005607 02361 550E ...

Page 118: ...STANDARD PARTS 550E MM149 5 01 6 48 Fig 32 Hydraulic Schematic 005608 11118 550E ...

Page 168: ...OPTIONS 550E MM149 9 99 8 18 ...

Page 182: ...BREAKDOWNS 550E MM149 10 10 9 14 ...