Smiths Medical International Ltd.

Issue 5 (August 2004)

3200 Service Manual

4 — 7

Once the switch-mode controller has started working, it obtains its power supply from a

bootstrap winding on pins 2 and 3 on the transformer. The power supply from the bootstrap

winding is rectified by diode D5, smoothed by C13 and regulated by the Zener diode D6.

The PWM signal output from pin 5 on IC1 controls the operation of Q3 causing it to cycle on

and off and regulate the flow of current from D7 through the primary winding. C1 and R1, C2

and R2, C3 and R4, C4 and R3 are all transient suppression circuits.

The voltage on pin 12 (IN1) of the secondary winding is rectified by diodes D1 and D3 (see

Figure 4.13

). The output from D1 is then smoothed by C6 and passed to pin 4 of PL11.

The DC output from D3 is filtered by C5, C7 and L1. The link to PL11 pin 3 is protected by

a 1 amp fuse, FS1.

When the mains supply is being used there is a voltage present on pin 4 of PL11. By using

R6 and R7 as a potential divider, this voltage is used to control Q2.

When there is no mains supply, Q2 is not active and so prevents the batteries from discharging

through R8, R9, RV1 and R10.

When Q2 is activated, R8, TH1, R9, RV1 and R10 form a potential divider between the output

of D3 and 0 V. The output from this is used as the reference voltage for the adjustable

precision shunt regulator D4. Capacitor C8 is a transient suppressor.

Thermistor TH1 varies the reference voltage according to temperature, thus compensating for

battery charging characteristics.

The feedback process occurs when the voltage at the wiper of RV1 exceeds the reference

value, D4 conducts and activates the opto-coupler IC2. The current through its photo-transistor

causes a voltage to be developed across resistor R19. This voltage is applied to IC1 which

changes the mark-space ratio of the output signal on pin 5.

An over voltage situation resulting from a malfunction in the regulator is prevented by a

crowbar protection device. When the output voltage exceeds 13 V, the Zener diode D2 conducts.

This causes a voltage to be developed across R5. This voltage is used to activate the silicon

controlled rectifier Q1 which will sink enough current to result in fuse FS1 blowing.

Regulator board

PL 11 output

PL12 output

See

Table 4.2 for the plug PL11 connections.

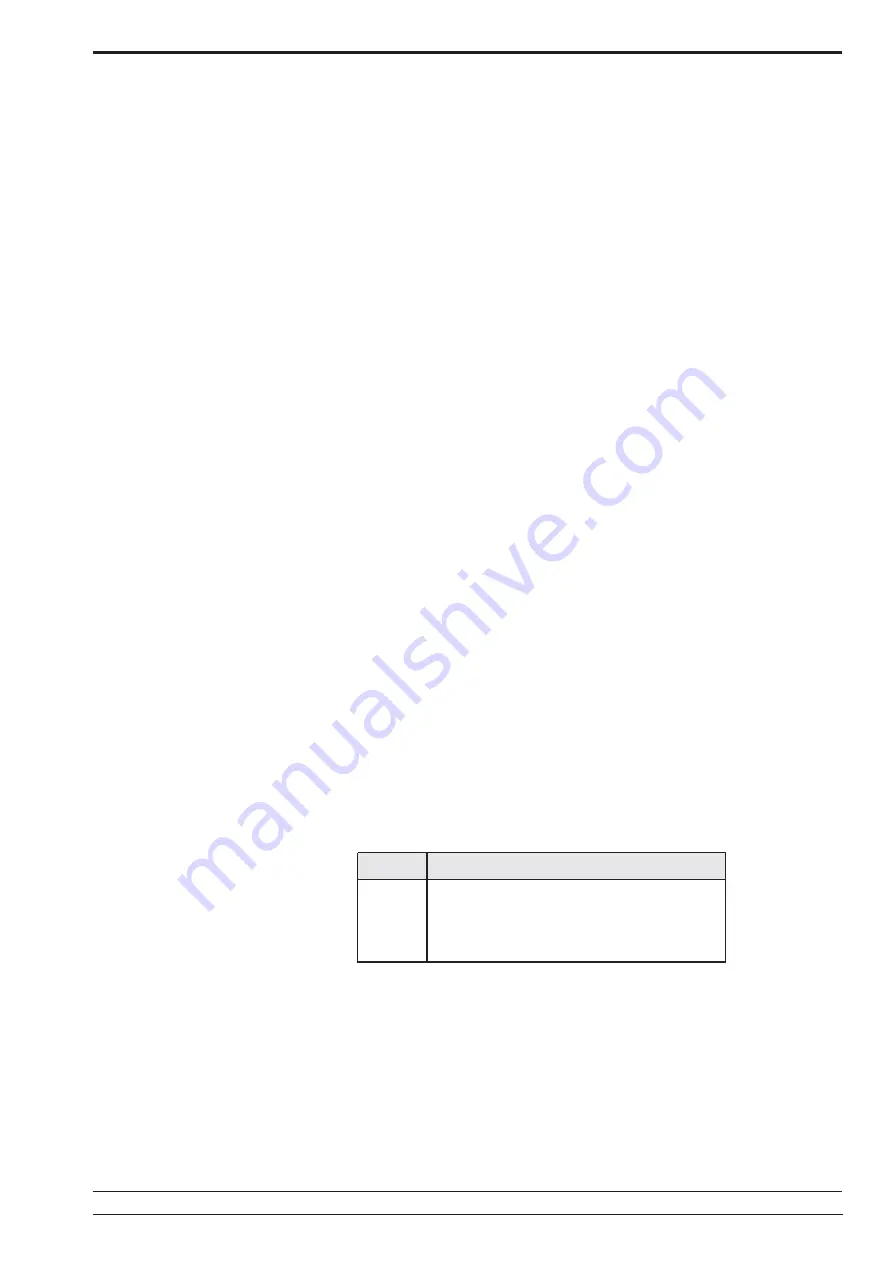

Table 4.2 PL11 connections

Pin

Output

1/2

Ground

3

7 V DC when on mains or battery supply

4

7 V DC when on mains supply

PL12 provides a link to the rechargeable batteries and the link is protected by FS3 a 2 amp

fuse.

Summary of Contents for Graseby 3200

Page 15: ...CHAPTER 1 INTRODUCTION FEATURES and SPECIFICATION 3200 In line Pressure Syringe Pump ...

Page 22: ...CHAPTER 2 CONFIGURATION DIAGNOSTICS and OCCLUSION THRUST 3200 In line Pressure Syringe Pump ...

Page 37: ...CHAPTER 3 FUNCTIONAL DESCRIPTIONS 3200 In line Pressure Syringe Pump ...

Page 43: ...CHAPTER 4 CIRCUIT DESCRIPTIONS 3200 In line Pressure Syringe Pump ...

Page 83: ...CHAPTER 6 FUNCTIONAL TESTS and MANUFACTURNG SETTINGS 3200 In line Pressure Syringe Pump ...

Page 91: ...CHAPTER 7 ILLUSTRATED PARTS LIST 3200 In line Pressure Syringe Pump ...

Page 105: ...CHAPTER 8 BRAUN PERFUSOR CONVERSION 3200 In line Pressure Syringe Pump ...

Page 108: ...CHAPTER 9 DC INPUT VERSION of 3200 3200 In line Pressure Syringe Pump ...

Page 111: ...APPENDIX FITTING a MODIFIED SIZE SENSOR FLAG 3200 In line Pressure Syringe Pump ...