Programming and Operating Manual (Milling)

178

6FC5398-4DP10-0BA1, 01/2014

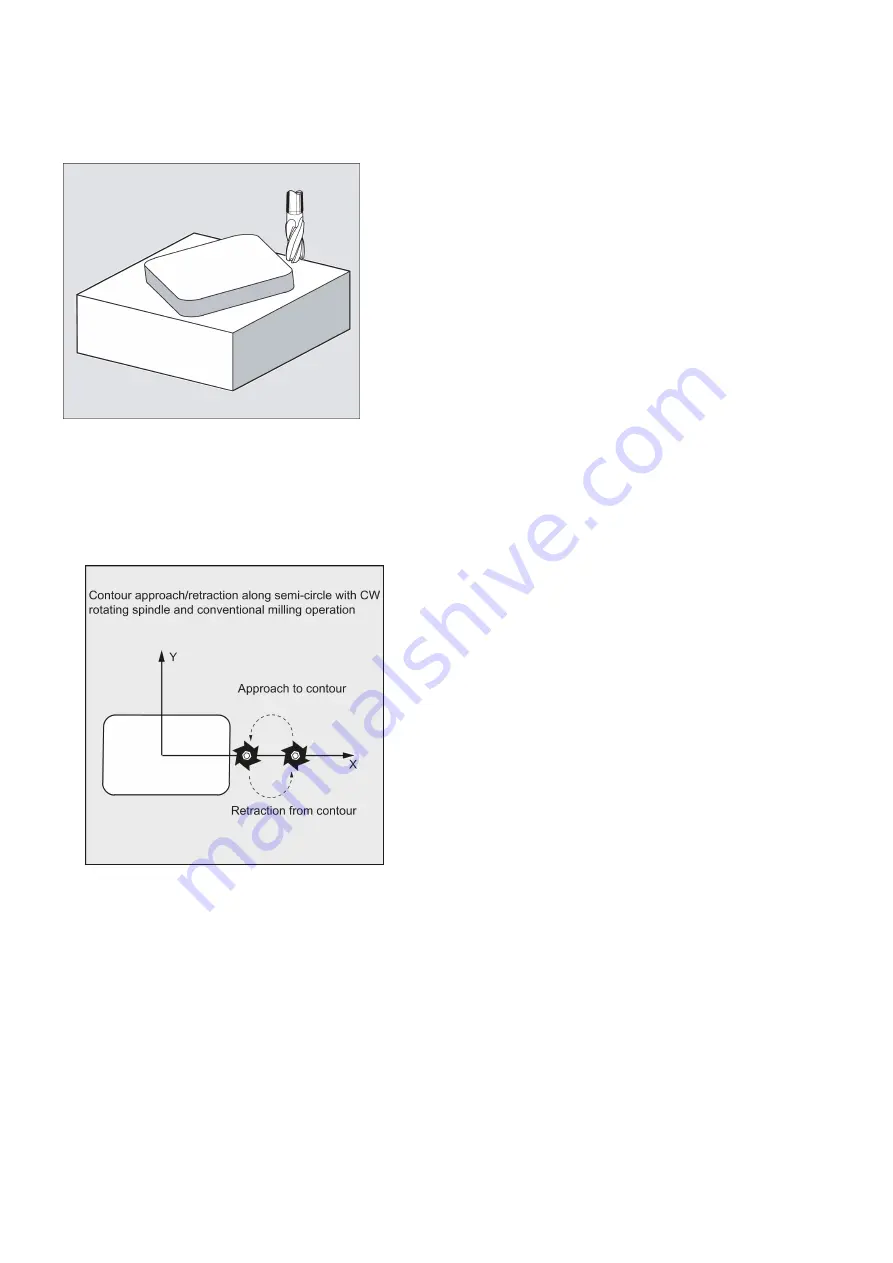

Function

Use this cycle to machine rectangular spigots in the machining plane. For finishing, a face cutter is required. The depth

infeed is always carried out in the position upstream of the semi-circle style approach to the contour.

Sequence

Position reached prior to cycle start:

The starting point is a position in the positive range of the abscissa with the approach semi-circle and the programmed raw

dimension on the abscissa end taken into account.

Sequence of motions when roughing (VARI=1):

●

Approach/retraction from contour:

The retraction plane (RTP) is approached at rapid traverse rate to then be able to position to the starting point in the

machining plane at this height. The starting point is defined with reference to 0 degrees of the abscissa.

The tool is fed to the safety clearance (SDIS) at rapid traverse with subsequent traversing to the machining depth at

feedrate. To approach the spigot contour, the tool travels along a semi-circular path.

The milling direction can be determined either as up-cut milling or down-cut milling with reference to the spindle direction.

If the spigot is bypassed once, the contour is left along a semi-circle in the plane, and the tool is fed to the next machining

depth.

The contour is then reapproached along a semi-circle and the spigot traversed once. This process is repeated until the

programmed spigot depth is reached. Then, the retraction plane (RTP) is approached at rapid traverse rate.

●

Depth infeed:

–

Feeding to the safety clearance

–

Insertion to machining depth